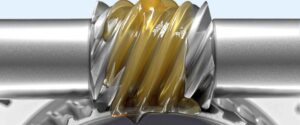

Grease serves as a critical lubricant for a multitude of machines and components across various industries. From automotive engines to vessels and factory machinery, the role of grease cannot be overstated. Each type of grease possesses unique properties that cater to specific applications—whether it’s in manufacturing, mining, construction, steel production, marine operations, or farming. Choosing the right grease results in optimal performance and durability of vehicles and equipment. In my experience working in the industry, understanding the versatility and application specifics of different types of lubricants has been crucial for ensuring everything stays well lubricated and runs smoothly.

Calcium grease, a lubricant crafted for general use, shines in settings demanding great water resistance and good corrosion protection. Its key features include great mechanical stability which holds its structure under varying pressures. This multipurpose grease is ideal for environments from lower temperatures to high temperatures without significant changes in performance. Predominantly manufactured for marine, industrial, automotive, and agricultural applications, it ensures smooth operations across diverse machinery.

Lithium grease, a multipurpose lubricant, excels due to its high viscosity and stability which provide long-lasting protection against oxidation and corrosion. Ideal for both automotive and industrial uses, this grease withstands extreme temperatures and severe wear and tear, making it a staple for metal-to-metal applications. Additionally, its lithium complex formulation enhances water resistance, perfect for gardening tools and household items subjected to high pressure and shock loads. Drawing from years of maintaining a fleet of farm equipment, I’ve noted that its durability significantly prolongs machinery life, proving indispensable in both planned maintenance and emergency repairs.

Aluminium Complex Grease, it’s imperative to grasp its nuanced advantages. This complex formulation offers unparalleled shear stability and remarkable water-resisting properties, making it an indispensable asset across diverse industries. Whether in the rigorous demands of the automotive sector, the exacting standards of the food industry, or the harsh conditions of steel milling and construction, this grease excels. Its ability to withstand high temperatures ensures optimal performance even in the most extreme environments, while simultaneously preventing rust, corrosion, and oxidation. With my extensive experience in lubrication solutions, I’ve witnessed firsthand the reliability and efficacy of Aluminium Complex Grease, making it my top recommendation for a myriad of applications in the farming industry and beyond.

Barium complex grease, one can’t help but marvel at its mechanical stability and oxidation stability. This high-performance grease stands as a stalwart guardian against the ravages of time and stress, boasting remarkable resistance to both high temperatures and heavy loads. Its versatility shines through in a myriad of demanding applications across industrial, aeronautical, marine, and manufacturing sectors. For machinery operating under intense conditions, where water tolerance and chemical resistance are paramount, the barium complex grease emerges as an indispensable ally. Its resilience under pressure and ability to withstand high speeds make it a cornerstone in the arsenal of lubrication solutions, ensuring smooth operations even in the harshest environments.

Bentone grease stands as a stalwart, a clay-based lubricant renowned for its steadfastness in the face of adversity. Crafted from the venerable bentonite clay, it embodies the essence of reliability, serving as a non-melt lubricant in the most arduous conditions. Its dropping point is a testament to its resilience against the relentless onslaught of heat, ensuring unfaltering performance amidst the most drastic temperature change resistance. Wear and tear protection is not just a feature but a commitment, shielding vital components from the ravages of time and friction. Its water tolerance is a boon, making it indispensable in environments where moisture lurks. For highly-demanding applications in the steel industry, manufacturing, construction, mining, and the ceramic industry, Bentone grease is the cornerstone of reliability, offering unmatched mechanical stability and shear stability. Its adhesiveness ensures it clings steadfastly to surfaces, providing enduring protection where it’s needed most.

Polyurea grease, one cannot overlook its durability and versatility. This exceptional lubricant boasts outstanding water resistance and great oxidation stability, making it a frontrunner in applications requiring robust rust and corrosion prevention. Its good mechanical stability ensures reliable performance even in demanding environments, while its high-temperature performance extends its utility across diverse industries. From the demanding conditions of steel plants to the precision requirements of electric motors, polyurea grease stands as a steadfast solution for long-life applications. Having navigated through various lubrication challenges, I’ve found polyurea grease to be an indispensable asset, seamlessly safeguarding machinery and equipment against wear and tear while optimizing operational efficiency.

Sodium grease, one cannot overlook its soda soap composition, a fundamental aspect defining its quality and value. Formulated with precision, sodium grease blends base oils with additives to ensure optimum lubrication across various applications. Its shear stability and dropping point make it ideal for rolling contact bearings under heavy loads. Moreover, sodium grease excels in rust protection and water resistance, crucial for marine and heavy-duty industries. With a focus on oxidation stability, this multipurpose grease stands as a cornerstone in automotive and industrial settings alike, offering unparalleled extreme pressure performance and enduring shear conditions.

When selecting the ideal grease for your specific application, several factors come into play, influencing your purchasing decision. Understanding your equipment’s requirements is paramount; the type of machinery, operating conditions, and environmental factors all play crucial roles. Consideration of temperature extremes, load-bearing capacities, and moisture exposure guides your selection process. Additionally, assessing compatibility with seals and other materials ensures seamless integration into your system. Drawing from my own experience in industrial maintenance, I’ve found that thorough research and consultation with experts are indispensable. Personal experience has shown that a well-informed decision leads to optimal equipment performance and longevity.

When it comes to lubricants, understanding the nuances of base oil is crucial for optimizing performance and ensuring protection across various applications. There are two primary categories: mineral and synthetic. Mineral oils, derived from refined crude oil, offer reliable temperature resistance and shear stability, making them ideal for conventional applications where cost-efficiency is paramount. On the other hand, synthetic oils, engineered for superior performance, boast exceptional weather resistance and extended service life, making them indispensable in demanding environments. Selecting the right base oil for your grease formulation is akin to choosing the foundation of a structure—it sets the stage for optimal protection and performance.

When it comes to grease, understanding its qualities and the role of additives is paramount for optimizing performance. Additives act as boosters, augmenting grease’s innate features. From extreme pressure additives to corrosion inhibitors, each additive serves a specific purpose in safeguarding machinery. Polymers contribute to adhesiveness, ensuring grease adheres to surfaces even under duress. Insoluble solids fortify the structure, offering unparalleled wear and tear protection. Dyes and pigments, though seemingly cosmetic, can signify crucial properties. Personal experience underscores the significance of choosing the right grease for the job, where the interplay of additives determines longevity and efficiency.

When it comes to grease, understanding the components is crucial for optimal performance. Thickeners play a pivotal role in defining the consistency of grease, determining its ability to bond effectively. From simple to complex formulations, thickeners like soaps, lithium, calcium, aluminium, sodium, and barium compounds, as well as non-soap types such as clay and polyurea, offer diverse options. Each thickener influences the grease’s properties differently, affecting its efficiency in various applications. Personal expertise guides the selection process, ensuring the optimal grease type for specific needs.

understanding its consistency is paramount. The National Lubricating Grease Institute (NLGI) has categorized grease into various grades based on their softness or hardness, denoted by NLGI numbers ranging from 000 to 6. These grades define the fluidity of the grease, ranging from very soft to very hard. Whether you’re dealing with a soft or firm grease, knowing its NLGI number helps in determining its suitability for specific applications. Each consistency level has its unique advantages, and understanding when to utilize very soft versus very hard grease can significantly impact performance and longevity.

viscosity is paramount. Viscosity serves as the bedrock of lubricant performance, dictating its stability and efficacy in various applications. Picture a spectrum where one end embodies higher viscosity oils, suited for heavy duty and slow loads, providing robust protection and stability under immense pressure. Conversely, at the opposite end, lower viscosity oils reign supreme, ideal for high-speed scenarios, where friction is the adversary. Mastery of viscosity empowers one to discern the perfect lubricant for each operational context, ensuring smooth operations and machinery longevity.

it’s vital to grasp the differences between automotive and industrial variants to ensure optimal performance and adherence to specific requirements. The composition and features of these greases play a pivotal role in their respective applications.

The formulation of grease hinges on several critical elements such as thickener type, lubricant type, and additive package. Understanding these components is crucial for effective application in various scenarios.

In the automotive industry, greases are often defined by two-letter designations like GC and LB, catering to specific components such as axles, wheel bearings, and chassis. This targeted approach ensures proper lubrication and protection against friction, wear, and corrosion.

Conversely, industrial greases are tailored to endure harsh conditions, including exposure to water, dirt, and heavy loads. The selection process here emphasizes factors like rust protection, film strength, and water resistance to prevent failure and ensure seamless operation.

Regardless of the context, grease selection should align with the specific application requirements, accounting for factors like speed, temperature, and contamination levels. Balancing oxidation stability and mechanical stability is key to achieving consistent performance across a wide temperature range.

Automotive grease serves as a vital lubrication tool in the arsenal of mechanics, acting as the unsung hero behind the scenes. It ensures that gears, bearings, joints, and other moving parts operate smoothly, reducing friction and preventing premature wear and tear. By extending the lifespan of crucial vehicle parts, it averts costly repairs and downtime, making it an essential component of automotive lubrication. Understanding the types of automotive grease and how to choose and apply them is crucial for effective vehicle operation, whether it’s a passenger car or a commercial truck.

As you can see, the type of grease you decide to use matters a lot.

Consulting with experts such as those at Valvoline Grease can provide invaluable insights and recommendations tailored to the unique performance and protection needs of your equipment and machinery. Their expertise extends to production and contact with a wide array of grease variants, ensuring that your selection aligns precisely with your operational requirements and delivers optimal performance and longevity.