Extend Your Tractor’s Lifespan with Rumanza UTTO Oil – A Comprehensive Guide

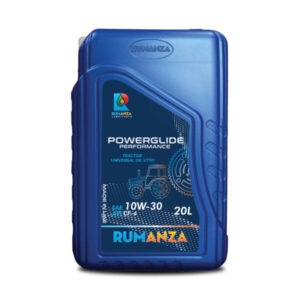

Tractors are the backbone of modern agriculture, performing demanding tasks such as plowing, tilling, hauling, and powering attachments. Given their heavy workload, ensuring optimal performance and longevity is crucial. One of the most effective ways to protect your tractor’s critical systems is by using Rumanza UTTO (Universal Tractor Transmission Oil), a high-performance lubricant engineered to enhance durability, efficiency, and reliability.

The Science Behind UTTO Oil: Why It Matters for Your Tractor

1. Multi-Functional Lubrication for Complex Systems

Modern tractors integrate transmission, hydraulic, wet brake, and final drive systems, all requiring specialized lubrication. Conventional oils may not provide adequate protection across all these components, leading to:

Increased wear and tear

Reduced hydraulic efficiency

Brake system degradation

Rumanza UTTO oil is a multi-grade, multi-purpose fluid designed to meet the needs of all these systems simultaneously. Its advanced additive package ensures:

Optimal gear shifting (transmission)

Smooth hydraulic operation (implements and loaders)

Reliable wet brake performance (stopping power)

Protection for final drive gears (durability under load)

2. How Rumanza UTTO Oil Reduces Friction and Wear

Friction is the primary enemy of tractor components. When metal parts rub against each other without proper lubrication, they generate heat and wear down over time.

Key Anti-Wear Mechanisms in Rumanza UTTO Oil:

Extreme Pressure (EP) Additives – Forms a protective layer on gear surfaces, preventing direct metal contact.

Anti-Scuffing Agents – Reduces micro-welding between gear teeth under heavy loads.

Molybdenum Disulfide (MoS₂) Compounds – Enhances lubrication in high-stress areas.

Result:

Extended gear life (up to 30% longer than standard oils)

Reduced maintenance costs (fewer breakdowns)

Smoother operation (less jerky gear shifts)

Thermal Stability and Oxidation Resistance: Keeping Your Tractor Cool Under Pressure

1. The Problem of Oil Breakdown in High-Temperature Environments

Tractors often operate in extreme heat, especially in tropical climates or during prolonged fieldwork. Standard oils can:

Oxidize and thicken, reducing flow efficiency

Form sludge, clogging filters and hydraulic valves

Lose viscosity, leading to metal-on-metal contact

2. How Rumanza UTTO Oil Maintains Stability

Advanced Oxidation Inhibitors – Slow down chemical breakdown, even at high temperatures.

Thermal Stabilizers – Prevent viscosity thinning, ensuring consistent lubrication.

Detergent Additives – Keep internal components clean by preventing sludge buildup.

Benefits:

Longer oil life (fewer oil changes required)

Better hydraulic response (no sluggishness in hot weather)

Reduced engine strain (less overheating risk)

Hydraulic System Performance: Why Fluid Quality Matters

1. The Role of UTTO Oil in Hydraulic Efficiency

A tractor’s hydraulic system powers implements like loaders, backhoes, and seed drills. If the oil is too thick or contaminated, it can cause:

Slow implement response

Pump cavitation (damage due to air bubbles)

Increased fuel consumption

2. How Rumanza UTTO Oil Enhances Hydraulics

Optimal Viscosity Index – Maintains fluidity in both cold starts and hot operations.

Anti-Foaming Agents – Prevents air entrapment, ensuring smooth hydraulic function.

High Shear Stability – Resists thinning under pressure, protecting pump components.

Real-World Impact:

Faster implement response (improves fieldwork efficiency)

Lower fuel consumption (reduced hydraulic resistance)

Extended pump life (fewer costly repairs)

Wet Brake Protection: Ensuring Safety and Longevity

1. The Challenge of Wet Brake Systems

Many modern tractors use oil-cooled wet brakes, where the transmission oil also lubricates brake discs. Poor-quality oils can lead to:

Brake fade (loss of stopping power under load)

Clutch slippage (reduced pulling power)

Corrosion in brake assemblies

2. How Rumanza UTTO Oil Improves Brake Performance

Friction Modifiers – Ensure consistent braking without excessive wear.

Corrosion Inhibitors – Protect brake discs and clutch plates from rust.

Thermal Resistance – Prevents brake fluid breakdown under high heat.

Result:

More reliable stopping power (critical for heavy loads)

Longer brake life (fewer replacements needed)

Smoother clutch engagement (less jerky operation)

Corrosion and Rust Prevention: Protecting Your Investment

1. The Hidden Danger of Moisture in Tractor Systems

Condensation, rainwater, and humidity can lead to internal rust in:

Transmission gears

Hydraulic cylinders

Final drive housings

2. How Rumanza UTTO Oil Fights Corrosion

Rust Inhibitors – Form a protective barrier on metal surfaces.

Water-Separating Additives – Prevent emulsification (oil-water mixing).

Acid Neutralizers – Counteract corrosive byproducts of oxidation.

Benefits:

Longer component lifespan (especially in humid climates)

Reduced downtime (fewer rust-related failures)

Better resale value (well-maintained tractors fetch higher prices)

Comparing Rumanza UTTO Oil with Competitor Products

| Feature | Rumanza UTTO Oil | Standard UTTO Oil | Premium Competitor X |

|---|---|---|---|

| Anti-Wear Protection | Extreme Pressure (EP) additives | Basic anti-wear agents | Moderate EP additives |

| Thermal Stability | Advanced oxidation resistance | Prone to breakdown at high temps | Good, but not as durable |

| Hydraulic Efficiency | Optimal viscosity in all conditions | Thickens in cold weather | Works well but foams under stress |

| Wet Brake Performance | Friction-stable formulation | May cause brake shudder | Decent but not optimal |

| Corrosion Resistance | Strong rust inhibitors | Minimal protection | Moderate protection |

| Price Efficiency | Longer drain intervals = cost savings | Frequent changes needed | Slightly more expensive |

Why Rumanza Wins:

✔ Superior additive technology

✔ Proven field performance

✔ Cost-effective in the long run

Best Practices for Maximizing Tractor Lifespan with Rumanza UTTO Oil

1. Regular Oil Analysis

Conduct oil sampling every 500 hours to check for contamination.

Look for metal particles, water content, and viscosity changes.

2. Follow Manufacturer’s Drain Intervals

Most tractors require UTTO oil changes every 1,000-1,500 hours.

In extreme conditions (dusty, wet, or high-load operations), change every 800 hours.

3. Always Use Genuine Filters

Cheap filters can bypass contaminants, reducing oil effectiveness.

Replace both oil and hydraulic filters during changes.

4. Store Oil Properly

Keep containers sealed to prevent moisture absorption.

Avoid direct sunlight to prevent additive degradation.

5. Monitor Tractor Performance

Watch for unusual noises, sluggish hydraulics, or gear slippage.

Address issues before they cause major damage.

Conclusion: Why Rumanza UTTO Oil is the Best Choice

Extending your tractor’s lifespan isn’t just about regular maintenance—it’s about using the right lubricant. Rumanza UTTO oil stands out due to its:

By choosing Rumanza UTTO oil, you’re not just maintaining your tractor—you’re investing in its future. Whether you’re a small-scale farmer or manage a large agricultural fleet, this oil ensures peak performance, fewer breakdowns, and lower long-term costs.

FAQs

Radiator Stop Leak UAE: Quick Fix for Vehicle Cooling System Leaks

Radiator Stop Leak UAE: Quick Fix for Vehicle Cooling System Leaks Discover More Introduction: The Unforgiving UAE Climate and Your Vehicle’s Lifeline The United Arab Emirates’ automotive landscape is defined by extremes. Ambient temperatures that regularly surpass 45°C (113°F), coupled with intense urban congestion and long, high-speed desert drives, create a perfect storm of thermal stress for every vehicle. In this environment, your engine cooling system is not merely a subsystem; it is the single most critical component preventing catastrophic engine failure.

What Type of Transmission Oil in UAE Does My Car Need? Your Complete Guide

What Type of Transmission Oil in UAE Does My Car Need? Your Complete Guide Discover More Navigating the vast, sun-baked highways of the United Arab Emirates—from the dynamic urban sprawls of Dubai and Abu Dhabi to the majestic desert dunes and the tranquil mountain passes of the Hajar range—places extraordinary mechanical and thermal stress on every component of your vehicle. While conscientious drivers often prioritize engine oil changes, the vital lifeblood safeguarding the transmission, the complex heart of your car’s

Guide to UAE Turbine Oil Selection Application & Management for Industrial Facilities

Guide to UAE Turbine Oil Selection, Application, and Management for Industrial Facilities Discover More In the hyper-competitive industrial landscape of the United Arab Emirates, where operational excellence directly translates to economic advantage, turbine lubrication represents a critical nexus of reliability engineering and strategic asset management. This comprehensive guide, developed with technical insights from Rumanza Lubricants, provides an unprecedented deep dive into the science, selection criteria, and life-cycle management of turbine oils specifically engineered for the extreme operating conditions of the

Synthetic vs. Mineral Hydraulic Oil in UAE : Which is Best for Your Operation?

Synthetic vs. Mineral Hydraulic Oil in UAE : Which is Best for Your Operation? Discover More Across the dynamic landscape of the United Arab Emirates—from the megaprojects of Dubai Marina to the intricate conveyor systems of Jebel Ali Port, from the massive hydraulic shovels in Al Dhafra quarries to the precision automated lines in Abu Dhabi’s industrial cities—the silent, powerful force of hydraulics is indispensable. These systems convert fluid power into monumental force and precise motion. At the core of

What is a Pour Point Depressant? | Benefits, Uses & How It Works Mechanism

What is a Pour Point Depressant? | Benefits, Uses & How It Works Mechanism Discover More In the intricate world of lubricant formulation, few additives play as critical yet understated a role in cold-weather operability as Pour Point Depressants (PPDs). These specialized chemical compounds are the linchpin that prevents machinery from seizing up when temperatures plummet. This in-depth guide goes beyond the basics, exploring the sophisticated chemistry, detailed mechanism, nuanced benefits, and practical considerations of PPDs. We will also examine the

Guide to Gasoline Engine Oils for UAE’s Extreme Climate: Engineering Peak Performance

Gasoline Engine Oils for UAE’s Extreme Climate: Engineering Peak Performance Discover More In the heart of the Arabian Peninsula, the United Arab Emirates stands as a testament to human ambition, with its engineering marvels and endless highways. Yet, this environment of soaring achievement is also one of the most punishing on Earth for machinery. For your vehicle—whether a nimble city sedan, a powerful family SUV, or a high-performance sports car—the UAE’s climate is a relentless adversary. The choice of engine

What are Polyol Ester Oils & Lubricants – Properties & Applications

What are Polyol Ester Oils & Lubricants – Properties & Applications Discover More In the intricate world of industrial machinery, automotive engines, and advanced refrigeration systems, the choice of lubricant is not merely a maintenance task—it’s a critical engineering decision. While conventional mineral oils have served us for over a century, the demands of modern technology require fluids that can perform under extreme pressure, temperature, and environmental stress. This is where synthetic lubricants, specifically Polyol Ester oils, come to the forefront.

Guide to Choosing the Right Lithium Complex Grease in UAE

Guide to Choosing the Right Lithium Complex Grease in UAE for Unbeatable Performance Discover More In the heart of a region defined by its ambition and extreme climate, the machinery that builds and powers the UAE operates under immense pressure. From the towering cranes sculpting Dubai’s skyline to the massive haul trucks in Abu Dhabi’s industrial zones and the relentless conveyor systems in Jebel Ali Port, every moving part is a critical link in the chain of progress. Protecting these