Agricultural Engine Oil in UAE: Tips for Agricultural Machinery

What Are Agricultural Lubricants For?

Agricultural lubricants are specially formulated oils and greases designed to minimize friction, reduce wear and tear, and protect machinery from corrosion. These lubricants are crucial for tractors, harvesters, and other farming equipment that operate under extreme conditions, including high temperatures, heavy loads, and dusty environments. Their primary functions include:

Reducing friction between moving parts

Preventing rust and corrosion

Enhancing fuel efficiency

Minimizing mechanical wear

Extending the lifespan of machinery

Providing thermal stability under extreme temperatures

Preventing the formation of sludge and deposits

Reducing oxidation, which can degrade oil quality

Types of Lubricants Used in Agricultural Applications

Agricultural machinery requires different types of lubricants based on their specific functions. The most commonly used lubricants include:

Engine Oil – Ensures smooth operation of tractor and harvester engines by reducing wear and tear. It also helps in maintaining an optimal temperature and preventing sludge buildup.

Hydraulic Fluids – Used in hydraulic systems to transfer power and lubricate components. They also prevent foaming and oxidation, ensuring efficiency.

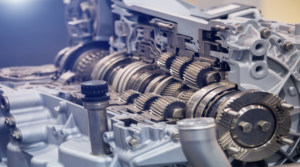

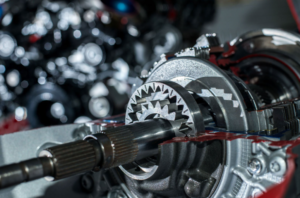

Gear Oil – Protects gears from wear and ensures smooth transmission operations by providing excellent load-carrying capability.

Greases – Ideal for lubricating moving parts such as bearings, joints, and bushings. They offer superior adhesion, protecting against water and contaminants.

Transmission Fluids – Essential for the proper functioning of the transmission system, ensuring smooth gear shifts and extending the life of clutches and gear components.

Coolants and Anti-Freeze – Helps regulate engine temperature and prevents overheating, reducing the risk of breakdowns.

Biodegradable Lubricants – Eco-friendly alternatives that reduce environmental impact while maintaining efficiency.

How to Maintain Agricultural Machinery?

Regular maintenance of agricultural machinery is crucial for ensuring optimal performance and avoiding costly repairs. Here are some essential tips:

Routine Inspections – Check for oil leaks, unusual noises, and worn-out parts.

Regular Oil Changes – Follow the manufacturer’s guidelines for oil change intervals to prevent engine wear.

Keep Machinery Clean – Remove dirt, dust, and debris to prevent contamination of lubricants, which can degrade their efficiency.

Check Oil Levels Frequently – Low oil levels can lead to increased friction, overheating, and mechanical failure.

Lubricate Moving Parts – Apply grease to necessary components to ensure smooth operation and prevent excessive wear.

Monitor Engine Performance – Watch for signs of reduced power or efficiency that could indicate oil-related issues.

Replace Filters – Oil and fuel filters should be changed regularly to prevent contamination and ensure optimal fluid flow.

Store Lubricants Properly – Keep lubricants in a dry, cool place to prevent degradation caused by heat and moisture exposure.

Factors That Affect the Oil

Several factors impact the performance and longevity of agricultural engine oil, including:

Operating Conditions – Extreme temperatures, heavy loads, and dust exposure can degrade oil faster.

Oil Quality – High-quality synthetic oils provide better protection and longevity compared to conventional oils.

Contaminants – Dirt, moisture, and metal particles can reduce oil effectiveness and lead to mechanical failures.

Usage Frequency – Frequent use of machinery requires more frequent oil changes to maintain peak efficiency.

Storage Conditions – Improper storage can lead to oil degradation, reducing its effectiveness in lubrication.

Compatibility with Equipment – Using the wrong type of oil can cause damage to seals, gaskets, and other engine components.

Benefits of Agricultural Engine Oil Lubrication

Using the right lubrication in agricultural machinery provides several benefits:

Enhanced Equipment Lifespan – Reduces wear and tear, extending the life of machinery significantly.

Improved Fuel Efficiency – Proper lubrication minimizes friction and reduces fuel consumption, helping farmers save on fuel costs.

Reduced Maintenance Costs – Prevents breakdowns and expensive repairs by ensuring components remain in optimal condition.

Smooth Operation – Ensures optimal performance under varying conditions, improving productivity and efficiency.

Protection Against Corrosion – Prevents rust and other forms of damage caused by moisture and exposure to harsh environments.

Reduction in Heat Generation – Proper lubrication helps dissipate heat, preventing overheating and damage to engine parts.

How to Know When Oil Is Due for a Change?

Timely oil changes are crucial for maintaining engine performance. Signs that indicate oil needs changing include:

Dark, thick, or gritty oil texture, indicating contamination and degradation.

Unusual engine noises or knocking sounds, suggesting increased friction.

Reduced fuel efficiency due to increased resistance in moving parts.

Overheating of machinery, which can result in serious damage.

Smoke or excessive exhaust emissions, which may indicate oil burning.

Warning lights on the dashboard indicating low oil pressure or engine issues.

The Importance of Diesel Tractor Oil

Diesel tractor oil is specifically formulated to meet the demands of heavy-duty agricultural engines. It helps in:

Reducing engine deposits and keeping the system clean.

Enhancing wear protection for critical components.

Improving fuel efficiency and performance under extreme conditions.

Maintaining viscosity to ensure proper lubrication.

Preventing sludge formation and oxidation.

Using the Right Diesel Tractor Oil

Choosing the right diesel tractor oil is essential for optimal performance. Consider the following factors:

Manufacturer Recommendations – Always follow the specifications provided by the tractor manufacturer.

Viscosity Grade – Select oil with the correct viscosity for the local climate and operating conditions.

Additives – Look for oils with anti-wear, detergent, and dispersant additives for enhanced performance.

Synthetic vs. Conventional – Synthetic oils offer better performance and longer drain intervals.

API and SAE Standards – Ensure the oil meets industry standards for quality and compatibility.

Which Parts of a Tractor Need Lubricating?

Proper lubrication of all critical components ensures efficient operation. Key parts that require lubrication include:

Engine – Requires high-quality engine oil to ensure smooth functioning.

Transmission System – Needs transmission fluid for smooth gear shifts.

Hydraulic System – Uses hydraulic oil to power various attachments efficiently.

Wheel Bearings – Require grease for smooth movement and reduced friction.

Steering Components – Need lubrication to ensure easy maneuverability and control.

PTO (Power Take-Off) Shaft – Must be greased to prevent wear and tear.

Brakes and Clutch System – Should be inspected and lubricated as necessary for smooth engagement.

Final Thoughts

Maintaining Agricultural Engine Oil Or machinery with proper lubrication is essential for efficiency and longevity, especially in the challenging conditions of the UAE. Using the right agricultural engine oil and following a strict maintenance schedule can save costs, reduce breakdowns, and enhance machinery performance. Farmers and agricultural operators should always prioritize high-quality lubricants and regular maintenance to ensure their equipment remains in optimal working condition.

FAQs

- Conventional Oil – Basic petroleum-based oil, suitable for older engines.

- Synthetic Oil – Offers superior performance, wear protection, and efficiency.

- Synthetic Blend Oil – A mix of conventional and synthetic oils, providing moderate protection.

- High-Mileage Oil – Specially formulated for vehicles with over 75,000 miles, reducing wear and oil leaks

- Distillate Fuel Oil – Includes diesel (No. 1 and No. 2 diesel) and heating oil.

- Residual Fuel Oil – Also called heavy fuel oil, used in ships and power plants.

- Kerosene-Based Fuels – Includes jet fuel and lamp oil.

0W-40 is a full synthetic engine oil used in high-performance and luxury vehicles, including sports cars, European cars (BMW, Mercedes, Audi), and turbocharged engines. It provides excellent cold-start performance and protection at high temperatures.

Does Your Car Need High Mileage Oil? (Signs You Should Switch)

Does Your Car Need High Mileage Oil? (Signs You Should Switch) Discover More As vehicles age, their engines undergo significant wear, leading to reduced efficiency and potential breakdowns. One of the most effective ways to maintain an older engine is by switching to high-mileage oil, specially formulated for cars with 75,000 miles or more. But how do you know if your car needs it? What are the key benefits, drawbacks, and alternatives? And why should you consider Ruamnza Xrace Pro Oil for your high-mileage vehicle?

Does Your Diesel Engine Need a Special Oil? (The Truth Revealed)

Does Your Diesel Engine Need a Special Oil? (The Truth Revealed) Discover More When it comes to maintaining a diesel engine, one of the most critical decisions you’ll make is choosing the right oil. Diesel engines operate under extreme conditions—high compression, intense heat, and heavy loads—which means they require a lubricant that can withstand these challenges. But does your diesel engine really need a special oil, or can you use any high-quality motor oil? In this comprehensive guide, we’ll uncover the

What is Anti-Freeze Coolant? Types, Colors & How to Use

What is Anti-Freeze Coolant? Types, Colors & How to Use Discover More Anti-freeze coolant, also known as engine coolant or radiator fluid, is a specially formulated liquid that regulates engine temperature, prevents overheating in summer, and protects against freezing in winter. It is a mixture of water, ethylene glycol or propylene glycol, and chemical additives that enhance engine efficiency and longevity. Without proper coolant, engines can suffer from: Overheating (leading to warped cylinder heads or blown gaskets) Freezing (causing cracked engine blocks in cold climates) Corrosion (damaging radiators,

What is ATF? Types of Transmission Fluid & When to Change It

What is ATF? Types of Transmission Fluid & When to Change It Discover More Transmission fluid is one of the most critical yet often overlooked components in a vehicle’s maintenance routine. Whether you drive an automatic, manual, continuously variable transmission (CVT), or dual-clutch transmission (DCT) vehicle, the right transmission fluid ensures smooth operation, longevity, and peak performance. What is Automatic Transmission Fluid (ATF)? Automatic Transmission Fluid (ATF) is a specialized lubricant designed to reduce friction, cool transmission components, and facilitate smooth

Fuel Injector Cleaner: Does It Really Work? (Analysis, Benefits, and Top Picks)

Fuel Injector Cleaner: Does It Really Work? (In-Depth Analysis, Benefits, and Top Picks) Discover More Modern engines rely on precise fuel delivery to maintain performance, efficiency, and emissions compliance. Fuel injectors play a critical role in this process by atomizing fuel into a fine mist for optimal combustion. However, over time, carbon deposits, varnish, and contaminants can clog injectors, leading to poor engine performance. Fuel injector cleaners are chemical additives designed to dissolve these deposits and restore injector efficiency. But do they

Best Railroad Engine Oils in 2025 – Boost Performance & Longevity

Best Railroad Engine Oils in 2025 – Boost Performance & Longevity Discover More The railroad industry is a backbone of global logistics, transporting millions of tons of cargo and passengers daily. Given the immense stress on locomotive engines, selecting the best railroad engine oil is crucial for optimal performance, fuel efficiency, and engine longevity. In 2025, advancements in lubrication technology have led to high-performance synthetic blends, low-ash formulations, and smart additives that enhance engine protection under extreme conditions. This guide

Best Transmission Treatments to Extend Your Vehicle’s Lifespan (2025 Guide)

Best Transmission Treatments to Extend Your Vehicle’s Lifespan Discover More Maintaining your vehicle’s transmission is crucial for ensuring longevity, smooth performance, and fuel efficiency. With advancements in automotive technology, transmission treatments have evolved significantly in 2025. This guide explores the best transmission treatments available, their benefits, and how they can help extend your vehicle’s lifespan. Understanding Transmission Systems and Their Importance A vehicle’s transmission is responsible for transferring power from the engine to the wheels, enabling smooth gear shifts and

What Is Xylene? Uses, Benefits & Safety Tips for Automotive & Industrial Applications

What Is Xylene? Uses, Benefits & Safety Tips for Automotive & Industrial Applications Discover More Xylene is a versatile hydrocarbon widely used in automotive, industrial, and chemical manufacturing due to its solvent properties. As a key component in paints, adhesives, and fuel additives, xylene plays a crucial role in various industrial processes. This article explores what xylene is, its primary uses, benefits in automotive and industrial applications, and essential safety tips for handling this chemical. Xylene is a colorless, flammable aromatic