Ashless Dispersant Chemical Additives: What They Are and How They Work

In the field of lubricants and engine oils, the inclusion of chemical additives is crucial to maintaining engine performance, prolonging the life of mechanical systems, and reducing emissions. Among these additives, ashless dispersants play a critical role in ensuring the cleanliness of engines and improving overall performance. But what are ashless dispersant chemical additives, and how exactly do they function within lubricants?

What Are Ashless Dispersant Chemical Additives?

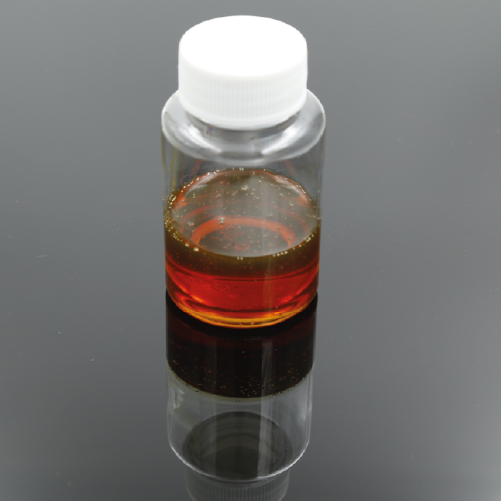

Ashless dispersant chemical additives are special types of compounds used in oils, particularly in engine lubricants, to prevent the buildup of harmful deposits such as sludge, varnish, and soot. The term “ashless” refers to the fact that these additives do not leave behind any solid residues (often called “ash”) when combusted. This characteristic makes them particularly valuable in applications where reducing emissions is a priority.

These additives belong to a broader category of dispersants, which are chemical compounds designed to keep solid particles suspended in a liquid, preventing them from accumulating on engine surfaces. Ashless dispersant detergent engine oil are primarily composed of long-chain hydrocarbon molecules with polar head groups that enable them to interact with various contaminants in the oil.

Composition of Ashless Dispersants

Ashless dispersants are made up of several key chemical components:

- Hydrocarbon Chains: These long chains form the backbone of the dispersant molecule and are responsible for the solubility of the additive in oil.

- Polar Head Groups: These groups are typically nitrogen or oxygen-based and are designed to interact with particles of soot, sludge, or other contaminants. By attaching to these particles, the polar head groups prevent them from agglomerating (clumping together).

- Non-Metallic: Unlike some other types of dispersants, ashless dispersants do not contain metal ions, which can leave residues upon combustion.

The result of this composition is an additive that effectively keeps contaminants suspended in the lubricant, allowing them to be carried away by the oil rather than forming deposits inside the engine.

How Do Ashless Dispersant Oil Work?

The primary function of dispersant additives is to maintain the cleanliness of the engine by preventing the buildup of deposits. When fuel burns in an engine, it generates byproducts such as carbon, soot, and unburnt hydrocarbons. Over time, these byproducts can accumulate on engine surfaces, leading to increased wear, reduced performance, and even engine failure. Here’s a step-by-step breakdown of how ashless dispersants work:

Suspending Contaminants: As engine oil circulates, ashless dispersants attach to contaminants such as soot and sludge. These contaminants are then kept in suspension within the oil, preventing them from settling on critical engine parts.

Preventing Agglomeration: Once contaminants are suspended, the dispersant molecules prevent them from sticking together and forming larger particles. This action ensures that the contaminants remain small and evenly distributed throughout the oil.

Facilitating Removal: By keeping contaminants suspended, ashless dispersants make it easier for the engine’s filtration system to remove them. When the oil is changed, these contaminants are drained away along with the oil, ensuring that the engine stays clean and operates efficiently.

Reducing Emissions: Because ashless dispersants do not contain metal ions, they do not produce ash when burned. This characteristic is particularly important in modern engines, which are designed to meet stringent emissions standards. Ashless dispersants help reduce the formation of harmful exhaust particulates, contributing to cleaner air.

Benefits of Ashless Dispersants

Premium Ashless oils offer several key benefits, making them a vital component in modern engine oils:

Engine Cleanliness: By preventing the buildup of sludge and varnish, ashless dispersants help maintain the cleanliness of critical engine components such as pistons, rings, and valves. A cleaner engine is more efficient and has a longer service life.

Extended Oil Life: By suspending contaminants and preventing deposit formation, ashless dispersants help extend the life of the oil. This means fewer oil changes are required, reducing maintenance costs for vehicle owners.

Improved Engine Performance: When engines are free of harmful deposits, they can operate at peak efficiency. This leads to better fuel economy, smoother operation, and reduced wear on engine parts.

Environmental Benefits: Ashless dispersants contribute to lower emissions by preventing the formation of particulates that would otherwise be released into the atmosphere. This makes them an important tool in the effort to reduce air pollution from internal combustion engines.

Applications of Ashless Dispersants

Ashless engine oil are widely used in various types of dispersant lubricant additives and oils, especially in like ashless 2 stroke oil etc:

Automotive Engine Oils: Modern cars, trucks, and motorcycles all benefit from the inclusion of ashless dispersants in their engine oils. These additives help keep engines running smoothly, reducing the likelihood of deposit-related problems.

Industrial Lubricants: In industrial applications, such as hydraulic systems and compressors, ashless dispersants play a crucial role in maintaining the cleanliness and efficiency of machinery. By preventing sludge and varnish buildup, these additives help reduce downtime and extend equipment life.

Marine and Aviation Oils: Ashless dispersants are also commonly used in marine and aviation lubricants, where cleanliness and reliability are paramount. The prevention of carbon and soot deposits is essential for the safe and efficient operation of engines in these demanding environments.

The Role of Ashless Dispersants in Modern Engine Oil Formulations

Dispersants in engine oil for modern engine oil formulations are complex blends of base oils and various additives, each serving a specific purpose. sustainable primary dispersant are just one of many additives used to enhance the performance of engine oils. Other common additives include:

- Anti-Wear Agents: These additives form a protective layer on metal surfaces, reducing wear and prolonging engine life.

- Detergents: Detergents help neutralize acids and keep the engine clean, working alongside dispersants to prevent deposit formation.

- Viscosity Index Improvers: These additives help maintain the oil’s viscosity across a wide temperature range, ensuring proper lubrication in both hot and cold conditions.

- Antioxidants: By preventing the oxidation of the oil, antioxidants help extend its service life and prevent the formation of harmful sludge and varnish.

In modern engine oils, ashless dispersants play a critical role in maintaining engine cleanliness and preventing deposit formation. Their ashless nature makes them especially valuable in applications where emissions control is important.

How Ashless Dispersants Differ from Other Additives

Ashless dispersants differ from other types of dispersants and detergent additives in that they do not contain metal-based components. Traditional detergent additives often include elements like calcium, magnesium, and sodium, which, while effective at neutralizing acids and cleaning engine surfaces, can leave behind metallic ash when burned. This ash can accumulate in engines and exhaust systems, leading to operational issues and reduced efficiency.

In contrast, dispersant lubricant additives suppliers in UAE are organic compounds that decompose cleanly, without leaving metallic residues. This makes them particularly suitable for engines with advanced emission control technologies, which can be negatively affected by ash buildup.

Final Thoughts

Ashless dispersant chemical additives are an essential component of modern engine oils and lubricants. Their ability to prevent the buildup of harmful deposits, reduce emissions, and extend the life of both the oil and the engine makes them invaluable in automotive, industrial, and marine applications. By keeping engines clean and operating efficiently, detergent dispersant additive contribute to improved performance, lower maintenance costs, and a cleaner environment. As emissions regulations continue to tighten, the importance of ashless dispersants in lubricant formulations will only increase, ensuring that engines remain clean, efficient, and environmentally friendly.

FAQs

Ashless dispersants do not contain metal ions, so they do not leave solid residues upon combustion. Metallic dispersants, on the other hand, may leave ash or other deposits that can negatively impact engine performance.

Because ashless dispersants do not produce solid residues or ash when burned, they help reduce the formation of harmful particulates that contribute to emissions, making them an important additive in complying with modern emission standards.

Ashless dispersants prevent the buildup of sludge and varnish, keeping the engine clean. This leads to better fuel efficiency, reduced wear on engine parts, and an extended service life for the engine.

Yes, by suspending contaminants and preventing them from forming deposits, ashless dispersants help extend the life of engine oil. This reduces the frequency of oil changes and lowers maintenance costs.

Ashless dispersants are used in various types of lubricants, including automotive engine oils, industrial lubricants, and even marine and aviation oils, wherever cleanliness and high performance are critical.

Radiator Stop Leak UAE: Quick Fix for Vehicle Cooling System Leaks

Radiator Stop Leak UAE: Quick Fix for Vehicle Cooling System Leaks Discover More Introduction: The Unforgiving UAE Climate and Your Vehicle’s Lifeline The United Arab Emirates’ automotive landscape is defined by extremes. Ambient temperatures that regularly surpass 45°C (113°F), coupled with intense urban congestion and long, high-speed desert drives, create a perfect storm of thermal stress for every vehicle. In this environment, your engine cooling system is not merely a subsystem; it is the single most critical component preventing catastrophic engine failure.

What Type of Transmission Oil in UAE Does My Car Need? Your Complete Guide

What Type of Transmission Oil in UAE Does My Car Need? Your Complete Guide Discover More Navigating the vast, sun-baked highways of the United Arab Emirates—from the dynamic urban sprawls of Dubai and Abu Dhabi to the majestic desert dunes and the tranquil mountain passes of the Hajar range—places extraordinary mechanical and thermal stress on every component of your vehicle. While conscientious drivers often prioritize engine oil changes, the vital lifeblood safeguarding the transmission, the complex heart of your car’s

Guide to UAE Turbine Oil Selection Application & Management for Industrial Facilities

Guide to UAE Turbine Oil Selection, Application, and Management for Industrial Facilities Discover More In the hyper-competitive industrial landscape of the United Arab Emirates, where operational excellence directly translates to economic advantage, turbine lubrication represents a critical nexus of reliability engineering and strategic asset management. This comprehensive guide, developed with technical insights from Rumanza Lubricants, provides an unprecedented deep dive into the science, selection criteria, and life-cycle management of turbine oils specifically engineered for the extreme operating conditions of the

Synthetic vs. Mineral Hydraulic Oil in UAE : Which is Best for Your Operation?

Synthetic vs. Mineral Hydraulic Oil in UAE : Which is Best for Your Operation? Discover More Across the dynamic landscape of the United Arab Emirates—from the megaprojects of Dubai Marina to the intricate conveyor systems of Jebel Ali Port, from the massive hydraulic shovels in Al Dhafra quarries to the precision automated lines in Abu Dhabi’s industrial cities—the silent, powerful force of hydraulics is indispensable. These systems convert fluid power into monumental force and precise motion. At the core of

What is a Pour Point Depressant? | Benefits, Uses & How It Works Mechanism

What is a Pour Point Depressant? | Benefits, Uses & How It Works Mechanism Discover More In the intricate world of lubricant formulation, few additives play as critical yet understated a role in cold-weather operability as Pour Point Depressants (PPDs). These specialized chemical compounds are the linchpin that prevents machinery from seizing up when temperatures plummet. This in-depth guide goes beyond the basics, exploring the sophisticated chemistry, detailed mechanism, nuanced benefits, and practical considerations of PPDs. We will also examine the

Guide to Gasoline Engine Oils for UAE’s Extreme Climate: Engineering Peak Performance

Gasoline Engine Oils for UAE’s Extreme Climate: Engineering Peak Performance Discover More In the heart of the Arabian Peninsula, the United Arab Emirates stands as a testament to human ambition, with its engineering marvels and endless highways. Yet, this environment of soaring achievement is also one of the most punishing on Earth for machinery. For your vehicle—whether a nimble city sedan, a powerful family SUV, or a high-performance sports car—the UAE’s climate is a relentless adversary. The choice of engine

What are Polyol Ester Oils & Lubricants – Properties & Applications

What are Polyol Ester Oils & Lubricants – Properties & Applications Discover More In the intricate world of industrial machinery, automotive engines, and advanced refrigeration systems, the choice of lubricant is not merely a maintenance task—it’s a critical engineering decision. While conventional mineral oils have served us for over a century, the demands of modern technology require fluids that can perform under extreme pressure, temperature, and environmental stress. This is where synthetic lubricants, specifically Polyol Ester oils, come to the forefront.