Furnace Oil and Lubricants: A Guide to Maximizing Equipment Life

In industries where heavy machinery is the backbone of production, ensuring the longevity and efficiency of equipment is vital. One of the most critical factors in maintaining and extending the life of industrial machinery is proper lubrication and the use of high-quality furnace oil. This guide will provide you with a comprehensive overview of furnace oil and lubricants, highlighting their roles in maximizing equipment life. We’ll also explore how the right choices in fuel oil furnaces, alongside regular maintenance and lubrication, can result in cost savings and enhanced operational efficiency.

What is Furnace Oil?

Furnace oil or furnace fuel oil is a type of fuel oil used predominantly in industrial boilers and furnaces for generating heat. It is a byproduct of crude oil and is highly viscous, requiring preheating before use in equipment. Best oil furnaces has a high calorific value, making it a preferred choice in industries that demand continuous, high-heat operations.

It refers to a unit of the furnace in which fuel fossil is consumed while heat is being transferred. Oil furnaces as well as the natural gas-fueled one are available types. An oil furnace is any heating system used to burn the fuel oil as a means to warm your house. Oil furnaces are, in fact common in colder-weather climates across the northeastern parts of the United States.

Furnace oil is mainly used in industries like power generation, steel, textiles, and chemical processing. Its cost-effectiveness and high efficiency in generating heat make it a popular option in industrial settings.

Key Properties of Furnace Oil:

High Calorific Value: Ensures efficient energy production.

Viscosity: Enables sustained combustion in industrial furnaces.

Stability: Prolongs shelf life and maintains consistent performance.

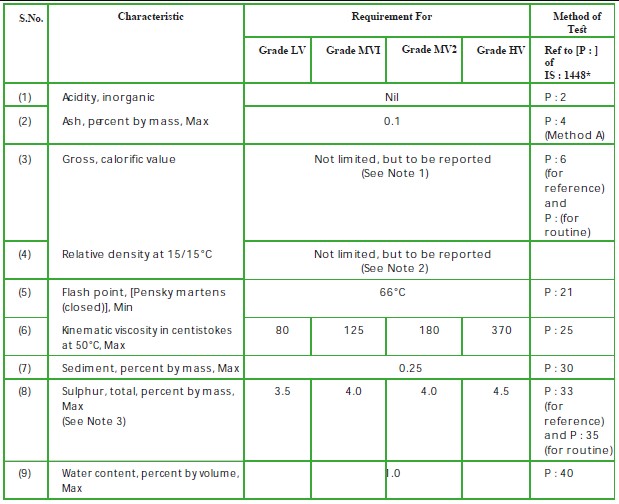

Typical Performance

How does an oil furnace work?

Types of Furnace Oils

Furnace oils come in different grades, ranging from lighter to heavier variants. The type of furnace oil you choose should depend on your equipment’s specific requirements and the operating conditions. Lighter oils tend to burn more efficiently, while heavier oils may provide a more sustained energy release.

When looking for the best oil furnaces, it’s essential to consider not only the type of oil used but also the furnace’s compatibility with that oil. Modern fuel oil furnace systems are often designed to handle a range of oil types, providing flexibility for industries that rely on varied fuel sources.

What’s the difference between an oil furnace and a gas furnace?

Pros and cons of oil furnaces

Pros:

- High Heat Output: Oil furnaces produce a high level of heat, making them ideal for colder climates where more heating power is needed.

- Independence from Gas Supply: Oil furnaces can operate in areas without access to natural gas lines, providing a reliable heating option.

- Affordable Equipment: The upfront cost of an oil furnace is often lower than other heating systems.

- Longevity: With proper maintenance, oil furnaces can last 15–25 years, offering long-term value.

- Energy Independence: Fuel oil can be stored on-site, giving homeowners control over their fuel supply.

Cons:

- Lower Efficiency: Oil furnaces tend to be less energy-efficient than gas furnaces, often resulting in higher fuel consumption.

- Maintenance Requirements: They require regular upkeep, including cleaning of burners and changing of filters, to prevent soot buildup and maintain efficiency.

- Cost of Fuel: Heating oil prices can fluctuate significantly, making annual heating expenses less predictable.

- Environmental Concerns: Burning oil emits more greenhouse gases compared to natural gas, contributing more to pollution.

- Storage Space: A storage tank for oil is necessary, which can take up significant space and may require periodic inspection and replacement.

Common Uses of Furnace Oil

Furnace oil finds application across various industries due to its reliability and cost-effectiveness:

Power Generation: A primary fuel for thermal power plants.

Industrial Heating: Used in kilns, boilers, and furnaces.

Marine Industry: Powers large engines in ships.

For those seeking reliable furnace oil suppliers in the UAE, the region boasts a robust market catering to industrial and commercial needs.

Fuel Oil Furnace: An Essential Tool for High-Efficiency Heating

A fuel oil furnace is specially designed to burn fuel oil like furnace oil, converting it into heat energy to power industrial operations. These furnaces are highly efficient, especially when the fuel oil is preheated for optimal combustion. Investing in a high-quality fuel oil furnace can help industries maximize energy efficiency while minimizing operational costs.

Role of Lubricants in Equipment Maintenance

While furnace oil is essential for heat generation, lubricants play a crucial role in reducing friction between the moving parts of machinery. Friction is one of the leading causes of equipment wear and tear. By minimizing friction, lubricants help extend the life of equipment, prevent breakdowns, and enhance overall efficiency.

Types of Lubricants Used in Industrial Equipment

- Mineral Oils: These are the most common lubricants derived from refining crude oil. They offer good stability and viscosity and are widely used in various industrial applications.

- Synthetic Oils: Offering better performance than mineral oils, synthetic oils provide improved resistance to oxidation and thermal breakdown, especially in high-temperature environments.

- Greases: These are semi-solid lubricants, often used in applications where liquid oils would leak away, such as in bearings or heavy-load machinery.

Regular use of lubricants prevents metal parts from grinding against each other, which in turn reduces the frequency of repairs and prolongs the life of the machinery.

Best Practices for Selecting the Best Oil Furnace

Choosing the best oil furnaces for your industrial operations involves several critical factors. Selecting the right furnace can have a profound impact on energy consumption, operational costs, and environmental sustainability.

Factors to Consider:

- Energy Efficiency: Opt for an oil furnace with a high Annual Fuel Utilization Efficiency (AFUE) rating. A higher AFUE means more energy is being converted into heat rather than wasted.

- Cost: The upfront cost of a furnace is important, but it’s also crucial to consider long-term operational costs. A cheaper oil furnace may result in higher energy bills and frequent maintenance.

- Size and Capacity: The oil furnace should be appropriately sized for the space it needs to heat. Oversized furnaces waste energy, while undersized ones may not meet operational demands.

- Environmental Impact: Look for oil furnaces that meet modern emissions standards to reduce your carbon footprint. Some modern oil furnaces now come with cleaner burning technology, making them more eco-friendly.

When selecting the best oil furnace, keep in mind your long-term goals in terms of efficiency and sustainability.

The Interplay Between Furnace Oil and Lubricants

Both furnace oil and lubricants play complementary roles in ensuring the longevity of industrial equipment. While furnace oil powers the heat generation process, lubricants ensure that the machinery runs smoothly without excessive wear and tear. The two work together to reduce operational costs and minimize downtime, ultimately enhancing overall productivity.

For example, in a steel plant, where heat generation is a constant necessity, using high-quality furnace oil ensures consistent heat output. At the same time, regular lubrication of the moving parts of the machinery prevents mechanical failures, ensuring that the production line continues without interruptions.

Maintaining Your Oil Furnace for Maximum Efficiency

Proper maintenance of your oil furnace is essential for maximizing its life and operational efficiency. Regular inspections and upkeep will not only extend the lifespan of the furnace but also prevent unexpected breakdowns that could disrupt industrial processes.

Used Oil Furnace Maintenance Tips:

- Regular Inspections: Schedule routine checks for any signs of wear, corrosion, or damage. Inspections will help identify potential issues before they become major problems.

- Clean Fuel Lines: Furnace oil can leave deposits in the fuel lines over time, reducing efficiency. Clean the fuel lines regularly to ensure smooth flow and optimal performance.

- Check for Fuel Leaks: Even small leaks can result in significant losses over time. Ensure that all fuel connections are tight and that no fuel is being wasted.

- Lubricate Moving Parts: Regularly lubricate the blower motor and other moving parts to prevent excessive friction and wear.

Following these best practices will ensure that your used oil furnace operates efficiently and effectively, minimizing downtime and maintenance costs.

Cost Considerations and Furnace Oil Prices

The cost of furnace oil can vary significantly based on factors such as location, crude oil prices, and demand. Monitoring furnace oil prices is critical for businesses relying on this fuel for their operations, as fluctuations in cost can directly impact their bottom line.

Strategies to Manage Furnace Oil Costs:

- Bulk Purchasing: Buying furnace oil in bulk can help lower the price per unit, especially when demand is low.

- Energy Audits: Conduct regular energy audits to identify areas where energy usage can be optimized. This can lead to more efficient use of furnace oil and reduce overall consumption.

- Regular Maintenance: Ensuring your furnace and machinery are in good working order can help prevent inefficiencies that lead to increased fuel consumption.

Investing in high-quality furnace oil and ensuring your equipment is properly maintained can help you avoid the pitfalls of fluctuating oil prices and unexpected equipment failures.

Waste Oil Furnace: A Sustainable Alternative

As industries prioritize sustainability, waste oil furnaces have gained traction. These systems recycle used oils, converting them into usable energy, reducing environmental impact, and lowering operational costs.

Benefits of Waste Oil Furnaces:

Environmental Conservation: Minimizes waste disposal issues.

Cost-Effectiveness: Reuses waste oils effectively.

Energy Efficiency: Provides consistent heating solutions.

Leading Suppliers in the UAE

If you are searching for reliable furnace oil suppliers in UAE the region offers unparalleled options, known for their commitment to quality and timely delivery. Whether it’s furnace oil suppliers in Dubai or other emirates, the UAE stands as a beacon for industrial excellence.

Final Thoughts

Choosing the right furnace oil and lubricants is crucial to maximizing the lifespan of your equipment. Whether you are running a fuel oil furnace or a used oil furnace, the quality of the oil and lubricants you use, combined with a proactive maintenance schedule, will have a significant impact on equipment performance. By staying informed about furnace oil prices and ensuring proper lubrication, businesses can reduce operational costs, prevent breakdowns, and extend the life of their valuable machinery.

FAQs

Does Your Car Need High Mileage Oil? (Signs You Should Switch)

Does Your Car Need High Mileage Oil? (Signs You Should Switch) Discover More As vehicles age, their engines undergo significant wear, leading to reduced efficiency and potential breakdowns. One of the most effective ways to maintain an older engine is by switching to high-mileage oil, specially formulated for cars with 75,000 miles or more. But how do you know if your car needs it? What are the key benefits, drawbacks, and alternatives? And why should you consider Ruamnza Xrace Pro Oil for your high-mileage vehicle?

Does Your Diesel Engine Need a Special Oil? (The Truth Revealed)

Does Your Diesel Engine Need a Special Oil? (The Truth Revealed) Discover More When it comes to maintaining a diesel engine, one of the most critical decisions you’ll make is choosing the right oil. Diesel engines operate under extreme conditions—high compression, intense heat, and heavy loads—which means they require a lubricant that can withstand these challenges. But does your diesel engine really need a special oil, or can you use any high-quality motor oil? In this comprehensive guide, we’ll uncover the

What is Anti-Freeze Coolant? Types, Colors & How to Use

What is Anti-Freeze Coolant? Types, Colors & How to Use Discover More Anti-freeze coolant, also known as engine coolant or radiator fluid, is a specially formulated liquid that regulates engine temperature, prevents overheating in summer, and protects against freezing in winter. It is a mixture of water, ethylene glycol or propylene glycol, and chemical additives that enhance engine efficiency and longevity. Without proper coolant, engines can suffer from: Overheating (leading to warped cylinder heads or blown gaskets) Freezing (causing cracked engine blocks in cold climates) Corrosion (damaging radiators,

What is ATF? Types of Transmission Fluid & When to Change It

What is ATF? Types of Transmission Fluid & When to Change It Discover More Transmission fluid is one of the most critical yet often overlooked components in a vehicle’s maintenance routine. Whether you drive an automatic, manual, continuously variable transmission (CVT), or dual-clutch transmission (DCT) vehicle, the right transmission fluid ensures smooth operation, longevity, and peak performance. What is Automatic Transmission Fluid (ATF)? Automatic Transmission Fluid (ATF) is a specialized lubricant designed to reduce friction, cool transmission components, and facilitate smooth

Fuel Injector Cleaner: Does It Really Work? (Analysis, Benefits, and Top Picks)

Fuel Injector Cleaner: Does It Really Work? (In-Depth Analysis, Benefits, and Top Picks) Discover More Modern engines rely on precise fuel delivery to maintain performance, efficiency, and emissions compliance. Fuel injectors play a critical role in this process by atomizing fuel into a fine mist for optimal combustion. However, over time, carbon deposits, varnish, and contaminants can clog injectors, leading to poor engine performance. Fuel injector cleaners are chemical additives designed to dissolve these deposits and restore injector efficiency. But do they

Best Railroad Engine Oils in 2025 – Boost Performance & Longevity

Best Railroad Engine Oils in 2025 – Boost Performance & Longevity Discover More The railroad industry is a backbone of global logistics, transporting millions of tons of cargo and passengers daily. Given the immense stress on locomotive engines, selecting the best railroad engine oil is crucial for optimal performance, fuel efficiency, and engine longevity. In 2025, advancements in lubrication technology have led to high-performance synthetic blends, low-ash formulations, and smart additives that enhance engine protection under extreme conditions. This guide

Best Transmission Treatments to Extend Your Vehicle’s Lifespan (2025 Guide)

Best Transmission Treatments to Extend Your Vehicle’s Lifespan Discover More Maintaining your vehicle’s transmission is crucial for ensuring longevity, smooth performance, and fuel efficiency. With advancements in automotive technology, transmission treatments have evolved significantly in 2025. This guide explores the best transmission treatments available, their benefits, and how they can help extend your vehicle’s lifespan. Understanding Transmission Systems and Their Importance A vehicle’s transmission is responsible for transferring power from the engine to the wheels, enabling smooth gear shifts and

What Is Xylene? Uses, Benefits & Safety Tips for Automotive & Industrial Applications

What Is Xylene? Uses, Benefits & Safety Tips for Automotive & Industrial Applications Discover More Xylene is a versatile hydrocarbon widely used in automotive, industrial, and chemical manufacturing due to its solvent properties. As a key component in paints, adhesives, and fuel additives, xylene plays a crucial role in various industrial processes. This article explores what xylene is, its primary uses, benefits in automotive and industrial applications, and essential safety tips for handling this chemical. Xylene is a colorless, flammable aromatic

Best Automotive Grease for High-Temp Performance (Buyer’s Guide)

Best Rumanza Automotive Grease for High-Temp Performance (Buyer’s Guide) Discover More Automotive grease is a crucial component in vehicle maintenance, ensuring smooth operation and longevity of mechanical parts. Among the various brands available, Rumanza automotive grease has emerged as a top choice for high-temperature performance, offering superior lubrication under extreme conditions. Whether you’re maintaining a passenger car, heavy-duty truck, or industrial machinery, selecting the right grease can significantly impact performance, fuel efficiency, and component lifespan. This comprehensive buyer’s guide explores the best Rumanza grease products designed for

Fuel System Cleaner: How It Works & Why Your Car Needs It

Fuel System Cleaner: How It Works & Why Your Car Needs It Discover More Modern vehicles rely on highly efficient fuel systems to deliver optimal performance, fuel economy, and reduced emissions. However, over time, carbon deposits, varnish, and other contaminants accumulate in critical components such as fuel injectors, intake valves, and combustion chambers. These deposits can lead to poor engine performance, reduced fuel efficiency, and increased emissions. Rumanza Fuel System Cleaner is a premium fuel additive designed to deep-clean, protect, and enhance your vehicle’s