Group 3 Base Oil: Reliable Group 3 Base Oil Suppliers

Group 3 Base Oil

Group 3 base oils are highly refined mineral oils that offer near-synthetic performance levels due to their extensive refining processes. These oils are characterized by their high viscosity index, excellent oxidation stability, and low volatility. The refining process involves severe hydrocracking and hydroisomerization, which significantly reduces the presence of impurities such as sulfur and aromatics. As a result, Group 3 base oils have a high proportion of saturated hydrocarbons, providing superior performance in terms of thermal stability and cleanliness. They are commonly used in high-performance automotive lubricants, industrial oils, and other demanding applications where longevity and reliability are crucial. While they are more cost-effective than fully synthetic oils (Group 4), they still deliver outstanding performance, making them a popular choice for many industries.

Advantages of Using Group 3 Base Oils

- Performance: High viscosity index ensures consistent performance across temperature ranges.

- Longevity: Enhanced oxidation stability extends the life of lubricants.

- Fuel Efficiency: Reduced friction improves fuel efficiency in engines.

- Purity: Low impurity levels minimize deposits and sludge formation.

- Versatility: Suitable for a wide range of applications including automotive and industrial uses.

- Cost-Effective: Offers a cost-effective alternative to synthetic oils with similar performance benefits.

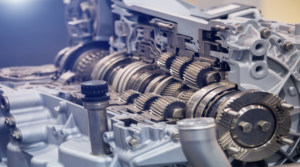

Applications of Group 3 Base Oils

In industrial settings, Group 3 base oils are used in hydraulic fluids, compressor oils, and turbine oils, where their thermal stability and long service life contribute to improved equipment reliability and efficiency. They are also employed in the manufacturing of metalworking fluids and greases, providing enhanced lubrication and protection in demanding processes. Additionally, Group 3 base oils are used in the formulation of synthetic lubricants, which offer superior performance in extreme conditions. Their versatility and high-performance properties make them a valuable component in various lubrication solutions across different industries.

What are Group 3 Base Oil Production Process

The production of base oils involves several key steps, starting with the extraction of crude oil. The crude oil is first heated and distilled in a fractionating column, where it is separated into various fractions based on boiling points. The heavier fractions, which contain the base oil feedstock, are then subjected to further refining processes. One of the primary refining techniques is solvent extraction, which removes unwanted aromatic compounds and improves the viscosity index of the oil.

This is followed by hydrocracking or catalytic dewaxing, where the oil is treated with hydrogen to remove impurities and enhance its stability and performance characteristics. The final step is hydrotreating, which further purifies the oil and improves its color and oxidation stability. The resulting base oils are then blended with various additives to produce finished lubricants that meet specific performance requirements. The entire production process is closely monitored to ensure the quality and consistency of the base oils.

- Extraction: Crude oil is extracted from the ground.

- Distillation: Crude oil is heated and separated into different fractions.

- Hydrotreating: Removes sulfur and other impurities.

- Hydrocracking: Breaks down large molecules into smaller ones.

- Isomerization: Converts molecules into isomers for better performance.

- Blending: Final base oil is blended with additives to enhance properties.

The Basic Properties of Base Oils

The flash point is the temperature at which the oil vapors can ignite, indicating the oil’s safety in high-temperature environments. Additionally, base oils should have good oxidation stability to resist degradation over time and thermal stability to perform well under high temperatures. These properties are critical for ensuring the reliability and efficiency of lubricants in various applications.

Group 3 Base Oil Specifications

The pour point is typically very low, allowing the oil to remain fluid in cold temperatures. The flash point is high, indicating good safety in high-temperature environments. Oxidation stability is another critical specification, as it determines the oil’s resistance to degradation over time. Additionally, Group 3 base oils have low volatility, reducing oil consumption and emissions. These specifications make Group 3 base oils suitable for a wide range of high-performance applications, including automotive, industrial, and power generation.

What are the Hydrogenation Process of Base Oils

The hydrogenation process is highly efficient and can be precisely controlled to produce base oils with specific properties tailored to different requirements. This advanced refining technique is essential for producing Group 3 base oils, which are known for their superior performance characteristics compared to conventional base oils.

What Are the Different Base Oil Groups?

Group 4 base oils are synthetic oils, specifically polyalphaolefins (PAOs), which are engineered for superior performance in extreme conditions. Group 5 base oils include all other types of synthetic and natural oils not covered by Groups 1-4, such as esters and silicones, which are used in specialized applications. Each group of base oils has unique properties that make them suitable for different types of lubricants and applications.

Are the API Group Classifications Progressively Better?

The API group classifications for base oils, ranging from Group 1 to Group 5, are not necessarily progressively better but rather different in terms of refining processes and performance characteristics. Group 1 base oils, being the least refined, have higher levels of sulfur and aromatics and are typically used in applications where cost is a major consideration.

Group 2 base oils offer better performance due to hydroprocessing, which reduces impurities and improves stability. Group 3 base oils, which undergo more extensive hydroprocessing, provide even higher performance with a higher viscosity index and better oxidation stability. Group 4 base oils, being synthetic polyalphaolefins (PAOs), offer the best performance in extreme conditions due to their engineered molecular structure.

Group 5 base oils include a wide range of synthetic and natural oils with specialized properties for specific applications. Therefore, the “better” classification depends on the specific performance requirements and application rather than a simple progression from Group 1 to Group 5.

Are Group 3 Base Oils "Synthetic?"

This includes a high viscosity index, excellent oxidation stability, and low volatility. In many regions, including Europe, Group 3 base oils are legally classified as synthetic. However, in the United States, the term “synthetic” is more commonly associated with Group 4 base oils, which are chemically engineered from pure chemical compounds. Despite this distinction, Group 3 base oils are widely recognized for their high performance and are used in many synthetic and semi-synthetic lubricants, offering a cost-effective alternative to Group 4 synthetics for many applications.

Are Synthetic Base Oils Magic?

These characteristics make synthetic base oils ideal for high-performance and extreme-condition applications, such as in high-speed engines, high-temperature industrial machinery, and low-temperature environments. Additionally, synthetic base oils tend to have longer service life and better compatibility with modern engine technologies, reducing the need for frequent oil changes and improving overall efficiency. While not magical, the advanced technology behind synthetic base oils offers tangible benefits that enhance the performance and longevity of lubricated equipment.

Group 3 vs Group 4 Oil

in uniform molecular structures that provide even greater performance benefits, such as higher thermal stability, better low-temperature fluidity, and longer service life. While Group 3 oils offer a cost-effective alternative to PAOs and are suitable for many high-performance applications, Group 4 oils are preferred for the most demanding environments and conditions due to their unparalleled stability and performance. The choice between Group 3 and Group 4 oils depends on the specific requirements of the application and the desired balance between cost and performance.

Group 3 Base Oil Suppliers: By Rumanza

“Rumanza” is a notable of Group 3 base oils supplier , recognized for its commitment to quality and innovation. As a key player in the lubricant industry, Rumanza produces high-quality Group 3 base oils that meet stringent performance standards. Their products are characterized by a high viscosity index, excellent oxidation stability, and low volatility, making them suitable for a wide range of demanding applications. Rumanza’s state-of-the-art production facilities utilize advanced hydroprocessing and hydrocracking technologies to ensure the purity and consistency of their base oils.

The company also invests in extensive research and development to continuously enhance the performance characteristics of their products, catering to the evolving needs of industries such as automotive, industrial machinery, and power generation. By offering technical support and customized solutions, Rumanza helps its customers optimize their lubrication processes and achieve greater efficiency and reliability in their operations. Their reputation for quality and innovation makes Rumanza a trusted supplier of Group 3 base oils in the global market.

Final Thoughts

Group 3 base oils, continuously investing in research and development to meet the evolving needs of their customers. Understanding the different base oil groups and the advantages of using Group 3 base oils can help industries make informed decisions about their lubrication needs, leading to improved efficiency, reduced downtime, and lower operational costs. Whether used in high-performance engine oils, industrial lubricants, or synthetic formulations, Group 3 base oils provide a reliable and cost-effective solution for modern lubrication challenges.

FAQs

Does Your Car Need High Mileage Oil? (Signs You Should Switch)

Does Your Car Need High Mileage Oil? (Signs You Should Switch) Discover More As vehicles age, their engines undergo significant wear, leading to reduced efficiency and potential breakdowns. One of the most effective ways to maintain an older engine is by switching to high-mileage oil, specially formulated for cars with 75,000 miles or more. But how do you know if your car needs it? What are the key benefits, drawbacks, and alternatives? And why should you consider Ruamnza Xrace Pro Oil for your high-mileage vehicle?

Does Your Diesel Engine Need a Special Oil? (The Truth Revealed)

Does Your Diesel Engine Need a Special Oil? (The Truth Revealed) Discover More When it comes to maintaining a diesel engine, one of the most critical decisions you’ll make is choosing the right oil. Diesel engines operate under extreme conditions—high compression, intense heat, and heavy loads—which means they require a lubricant that can withstand these challenges. But does your diesel engine really need a special oil, or can you use any high-quality motor oil? In this comprehensive guide, we’ll uncover the

What is Anti-Freeze Coolant? Types, Colors & How to Use

What is Anti-Freeze Coolant? Types, Colors & How to Use Discover More Anti-freeze coolant, also known as engine coolant or radiator fluid, is a specially formulated liquid that regulates engine temperature, prevents overheating in summer, and protects against freezing in winter. It is a mixture of water, ethylene glycol or propylene glycol, and chemical additives that enhance engine efficiency and longevity. Without proper coolant, engines can suffer from: Overheating (leading to warped cylinder heads or blown gaskets) Freezing (causing cracked engine blocks in cold climates) Corrosion (damaging radiators,

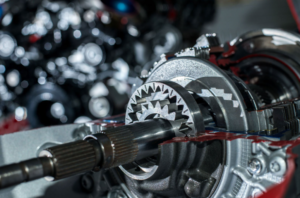

What is ATF? Types of Transmission Fluid & When to Change It

What is ATF? Types of Transmission Fluid & When to Change It Discover More Transmission fluid is one of the most critical yet often overlooked components in a vehicle’s maintenance routine. Whether you drive an automatic, manual, continuously variable transmission (CVT), or dual-clutch transmission (DCT) vehicle, the right transmission fluid ensures smooth operation, longevity, and peak performance. What is Automatic Transmission Fluid (ATF)? Automatic Transmission Fluid (ATF) is a specialized lubricant designed to reduce friction, cool transmission components, and facilitate smooth

Fuel Injector Cleaner: Does It Really Work? (Analysis, Benefits, and Top Picks)

Fuel Injector Cleaner: Does It Really Work? (In-Depth Analysis, Benefits, and Top Picks) Discover More Modern engines rely on precise fuel delivery to maintain performance, efficiency, and emissions compliance. Fuel injectors play a critical role in this process by atomizing fuel into a fine mist for optimal combustion. However, over time, carbon deposits, varnish, and contaminants can clog injectors, leading to poor engine performance. Fuel injector cleaners are chemical additives designed to dissolve these deposits and restore injector efficiency. But do they

Best Railroad Engine Oils in 2025 – Boost Performance & Longevity

Best Railroad Engine Oils in 2025 – Boost Performance & Longevity Discover More The railroad industry is a backbone of global logistics, transporting millions of tons of cargo and passengers daily. Given the immense stress on locomotive engines, selecting the best railroad engine oil is crucial for optimal performance, fuel efficiency, and engine longevity. In 2025, advancements in lubrication technology have led to high-performance synthetic blends, low-ash formulations, and smart additives that enhance engine protection under extreme conditions. This guide

Best Transmission Treatments to Extend Your Vehicle’s Lifespan (2025 Guide)

Best Transmission Treatments to Extend Your Vehicle’s Lifespan Discover More Maintaining your vehicle’s transmission is crucial for ensuring longevity, smooth performance, and fuel efficiency. With advancements in automotive technology, transmission treatments have evolved significantly in 2025. This guide explores the best transmission treatments available, their benefits, and how they can help extend your vehicle’s lifespan. Understanding Transmission Systems and Their Importance A vehicle’s transmission is responsible for transferring power from the engine to the wheels, enabling smooth gear shifts and

What Is Xylene? Uses, Benefits & Safety Tips for Automotive & Industrial Applications

What Is Xylene? Uses, Benefits & Safety Tips for Automotive & Industrial Applications Discover More Xylene is a versatile hydrocarbon widely used in automotive, industrial, and chemical manufacturing due to its solvent properties. As a key component in paints, adhesives, and fuel additives, xylene plays a crucial role in various industrial processes. This article explores what xylene is, its primary uses, benefits in automotive and industrial applications, and essential safety tips for handling this chemical. Xylene is a colorless, flammable aromatic

Best Automotive Grease for High-Temp Performance (Buyer’s Guide)

Best Rumanza Automotive Grease for High-Temp Performance (Buyer’s Guide) Discover More Automotive grease is a crucial component in vehicle maintenance, ensuring smooth operation and longevity of mechanical parts. Among the various brands available, Rumanza automotive grease has emerged as a top choice for high-temperature performance, offering superior lubrication under extreme conditions. Whether you’re maintaining a passenger car, heavy-duty truck, or industrial machinery, selecting the right grease can significantly impact performance, fuel efficiency, and component lifespan. This comprehensive buyer’s guide explores the best Rumanza grease products designed for