How to Choose the Best High Speed Bearing Grease for Your Machinery

High-speed bearing grease is essential for the smooth and efficient operation of machinery. Proper lubrication not only enhances performance but also extends the lifespan of the bearings. This guide aims to provide comprehensive insights into selecting the best high-speed bearing grease for your machinery, ensuring optimal performance and reliability.

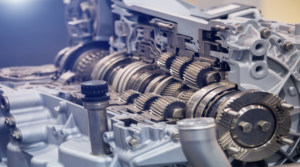

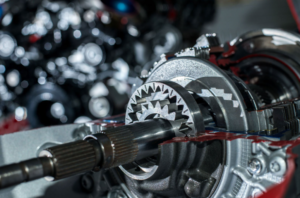

Understanding High-Speed Bearings

Key Factors to Consider When Choosing Grease

Operating Speed

The rotational speed, measured in revolutions per minute (RPM), significantly impacts grease selection. High-speed applications require grease that can withstand the centrifugal forces and maintain its lubricating properties without breaking down.

Temperature Range

Operating temperatures can vary widely in high-speed applications. It is crucial to select grease that remains stable and effective across the entire temperature range, preventing breakdowns or thickening that could hinder performance.

Load Carrying Capacity

Bearings may be subjected to various loads, including radial and axial forces. The chosen grease should contain additives that enhance its load-carrying capacity, ensuring it can handle the stresses imposed by the machinery.

Environmental Conditions

Machinery often operates in environments exposed to dust, water, and chemicals. The grease should offer robust protection against contaminants and be compatible with seals and materials used in the bearings.

Grease Consistency and Viscosity

The consistency of grease is indicated by its NLGI grade, while viscosity relates to its flow characteristics. Selecting the appropriate grade and viscosity ensures optimal lubrication and performance.

Types of High-Speed Bearing Grease

Mineral Oil-Based Grease

Synthetic Oil-Based Grease

Specialty Grease

Performance Characteristics of Bearing Grease

Wear Protection

Anti-wear additives are crucial for reducing friction and preventing wear. Evaluating the wear protection performance of grease ensures long-term reliability.

Oxidation Resistance

Grease must resist oxidation to maintain its properties over time. High oxidation stability prevents the grease from hardening or forming deposits, which can impair performance.

Corrosion Protection

Corrosion inhibitors in grease protect bearings from moisture and corrosive elements. Ensuring robust corrosion protection is vital for machinery operating in harsh environments.

Shear Stability

Shear stability refers to the grease’s ability to maintain consistency under mechanical stress. High shear stability ensures the grease remains effective during prolonged use.

Practical Steps to Selecting the Right Grease

Assessing Machinery Requirements

Identify the specific needs of your machinery by consulting manuals and manufacturer recommendations. Understanding these requirements is the first step in choosing the appropriate grease.

Conducting Grease Compatibility Tests

Compatibility tests are essential to ensure the new grease will work well with any existing lubricants. This prevents potential issues that could arise from mixing incompatible greases.

Evaluating Product Specifications and Certifications

Review technical data sheets to understand the specifications of the grease. Check for industry standards and certifications that validate the product’s performance and reliability.

Seeking Expert Advice

Consult lubrication experts and utilize manufacturer support services for guidance. Their expertise can help you make informed decisions and select the best grease for your needs.

Application and Maintenance Tips

Proper Grease Application Techniques

Use appropriate methods and tools for applying grease to bearings. Ensure even distribution to achieve optimal lubrication.

Routine Maintenance Practices

Implement regular inspection and re-lubrication schedules. Monitoring the condition of bearings and grease helps in early detection of potential issues.

Troubleshooting Common Issues

Learn to identify signs of lubrication failure, such as unusual noise, increased temperature, or vibration. Addressing these issues promptly prevents further damage and ensures continuous operation.

Final Thoughts

FAQs

Does Your Car Need High Mileage Oil? (Signs You Should Switch)

Does Your Car Need High Mileage Oil? (Signs You Should Switch) Discover More As vehicles age, their engines undergo significant wear, leading to reduced efficiency and potential breakdowns. One of the most effective ways to maintain an older engine is by switching to high-mileage oil, specially formulated for cars with 75,000 miles or more. But how do you know if your car needs it? What are the key benefits, drawbacks, and alternatives? And why should you consider Ruamnza Xrace Pro Oil for your high-mileage vehicle?

Does Your Diesel Engine Need a Special Oil? (The Truth Revealed)

Does Your Diesel Engine Need a Special Oil? (The Truth Revealed) Discover More When it comes to maintaining a diesel engine, one of the most critical decisions you’ll make is choosing the right oil. Diesel engines operate under extreme conditions—high compression, intense heat, and heavy loads—which means they require a lubricant that can withstand these challenges. But does your diesel engine really need a special oil, or can you use any high-quality motor oil? In this comprehensive guide, we’ll uncover the

What is Anti-Freeze Coolant? Types, Colors & How to Use

What is Anti-Freeze Coolant? Types, Colors & How to Use Discover More Anti-freeze coolant, also known as engine coolant or radiator fluid, is a specially formulated liquid that regulates engine temperature, prevents overheating in summer, and protects against freezing in winter. It is a mixture of water, ethylene glycol or propylene glycol, and chemical additives that enhance engine efficiency and longevity. Without proper coolant, engines can suffer from: Overheating (leading to warped cylinder heads or blown gaskets) Freezing (causing cracked engine blocks in cold climates) Corrosion (damaging radiators,

What is ATF? Types of Transmission Fluid & When to Change It

What is ATF? Types of Transmission Fluid & When to Change It Discover More Transmission fluid is one of the most critical yet often overlooked components in a vehicle’s maintenance routine. Whether you drive an automatic, manual, continuously variable transmission (CVT), or dual-clutch transmission (DCT) vehicle, the right transmission fluid ensures smooth operation, longevity, and peak performance. What is Automatic Transmission Fluid (ATF)? Automatic Transmission Fluid (ATF) is a specialized lubricant designed to reduce friction, cool transmission components, and facilitate smooth

Fuel Injector Cleaner: Does It Really Work? (Analysis, Benefits, and Top Picks)

Fuel Injector Cleaner: Does It Really Work? (In-Depth Analysis, Benefits, and Top Picks) Discover More Modern engines rely on precise fuel delivery to maintain performance, efficiency, and emissions compliance. Fuel injectors play a critical role in this process by atomizing fuel into a fine mist for optimal combustion. However, over time, carbon deposits, varnish, and contaminants can clog injectors, leading to poor engine performance. Fuel injector cleaners are chemical additives designed to dissolve these deposits and restore injector efficiency. But do they

Best Railroad Engine Oils in 2025 – Boost Performance & Longevity

Best Railroad Engine Oils in 2025 – Boost Performance & Longevity Discover More The railroad industry is a backbone of global logistics, transporting millions of tons of cargo and passengers daily. Given the immense stress on locomotive engines, selecting the best railroad engine oil is crucial for optimal performance, fuel efficiency, and engine longevity. In 2025, advancements in lubrication technology have led to high-performance synthetic blends, low-ash formulations, and smart additives that enhance engine protection under extreme conditions. This guide

Best Transmission Treatments to Extend Your Vehicle’s Lifespan (2025 Guide)

Best Transmission Treatments to Extend Your Vehicle’s Lifespan Discover More Maintaining your vehicle’s transmission is crucial for ensuring longevity, smooth performance, and fuel efficiency. With advancements in automotive technology, transmission treatments have evolved significantly in 2025. This guide explores the best transmission treatments available, their benefits, and how they can help extend your vehicle’s lifespan. Understanding Transmission Systems and Their Importance A vehicle’s transmission is responsible for transferring power from the engine to the wheels, enabling smooth gear shifts and