Importance of Xylene Petrochemicals: In Automotive Performance

Xylene petrochemical is one of the main petrochemicals derived from crude oil and is a highly important component in the automobile sector. Xylene is a colorless liquid with a pungent sweet smell and is utilized in the production of numerous auto parts. It has been extensively used to enhance performance of a car apart from using it in producing most auto parts. Knowing the importance of xylene in automobile applications can be very significant to manufacturers, engineers, and consumers at large.

Understanding Xylene and Its Types

Xylene is a member of the aromatic hydrocarbon family, derived from the refining of crude oil. It exists in three isomeric forms:

Ortho-Xylene (o-Xylene): Primarily used in the production of solvents, plastics, and coatings. It possesses excellent solvent properties, making it a preferred choice for paint formulations.

Meta-Xylene (m-Xylene): While less commonly used in automotive applications, it plays a role in producing certain types of plastics and is sometimes used in chemical synthesis.

Para-Xylene (p-Xylene): Widely utilized in the manufacturing of polyester fibers, films, and resins, para-xylene is also an essential component in creating various automotive materials.

Understanding these xylene types allows manufacturers to select the most appropriate form for their specific automotive needs, ensuring optimal performance and functionality.

Chemical Properties of Xylene that Enhance Automotive Performance

The molecular structure of xylene is what makes it so useful in automotive applications. There are three different isomers that make up the compound, hence, it exhibits a unique combination of properties as regards volatility, solvency, and stability. Specifically, xylene possesses high volatility, which is quite beneficial for fuel-related applications since it propels the progress aimed at improving efficiency with combustion processes in engines. Because of their solvency properties, xylene are an essential component of paint formulations, adhesives, and coatings applied in the different stages of automotive manufacture.

The third characteristic of xylene is its ability to serve as a good octane booster. The ability of xylene to prevent premature ignition or “knock” aids in providing an even flow of the engine in the combustion process. The chemical stability of xylene assures that it will have the endurance for the tough environments, hence it is applied in activities such as fuel additives and engine lubricants.

Xylene as a Fuel Additive: Improving Combustion and Engine Performance

One of the most significant uses of xylene in the automobile industry is an additive for fuel. When combined with gasoline, xylene assists in the enhancement of the octane rating of the fuel, which is significant for an engine to maintain performance. Higher compression ratios are permitted in more aggressive settings because higher compression ratios prevent the engine from knocking. In summary, this feature has some very positive implications:

- Better Engine Performance: Higher octane rating capability of xylene results in more efficient combustion. Thus, fuel economy is improved along with lesser emissions.

- Improved Power Output: Vehicles running with fuel containing xylene can hope for much higher power. The user will feel better acceleration and hence better performance characteristics overall.

- Lower Scent of Knocking the Engine: The possibilities of engine knock are minimized with xylene. The engine operation will be smoother and thus longer life for the engine.

This puts xylene at an advantage as the primary additive in performance-oriented vehicles as well as those that are non-performance-oriented but merely intend to ensure efficiency.

Enhancing Automotive Paints and Coatings

Xylene’s solvent characteristic establishes it as an integral part of car paints and coatings. It dissolves resins and pigments easily for easy application to the vehicle body surface in a uniform manner. The benefits of xylene include the following:

- Durability and Gloss: Xylene-coated materials display an added glossy finish for aesthetic appeal on vehicles. It boasts good durability against chipping or scratching as it remains resistant to environmental factors.

- Chemical Resistance: Xylene-based paints provide better chemical resistance, where the outside of the vehicle is better protected against hostile chemicals that the vehicle might encounter on a road.

- Application Versatility: Xylene-based resins can be easily formulated with many other resins. This provides flexibility in producing various automotive finishes and performance standards.

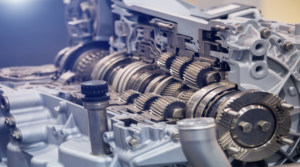

Xylene’s Role in Lubricants and Greases for Engine Efficiency

Another prominent use of xylene within the automobile industry is in the manufacture of high-performance lubricants and greases. These are vital in reducing friction between moving parts within the engine and other mechanical systems so that efficiency is gradually built, and wear is gradually reduced. Xylene-based greases and lubricants thus exhibit exceptional thermal stability, which enables them to withstand the extremely high temperatures produced by high-performance engines.

Xylene-based lubricants also reduce friction, thus assisting in the fuel efficiency of the vehicle and lessening the wear and tear on average engine parts. Such results in the longevity of engines, reduced maintenance calls, and reliability of vehicles. Xylene-based lubricants are critical for high-performance and commercial vehicles since they are operated under more severe conditions.

Xylene in Plastic and Rubber Manufacturing for Vehicles

Besides its main use in fuel additives and coatings, xylene has become an essential raw material in making plastic and rubber vehicle parts. This solvent xylene is an integral part of a process of producing lightweight yet strong parts made of plastics, which modern automobiles carry to reduce the weight and increase mileage. From the dashboard to exterior trims, plastics based on xylene can be seen throughout an automobile.

Another significant application of xylene is in the formulation of rubber compounds used to manufacture tires and other auto parts. Rubber prepared with xylene possesses a lot of elasticity and resistance, making it highly wanted to be used in the tires designed to be put under differing temperatures and road conditions. Enhanced plastic and rubber components, therefore, comprise an overall pathway to efficiency, safety, and longevity for any given vehicle.

Innovations and Sustainability in Xylene Applications

Current innovations in xylene applications are no longer just nontoxic but less harmful and more environmentally friendly while not compromising the characteristic performance advantages. In fact, bio-based alternatives to xylene are currently under study with similar properties but sourced from renewable energy rather than petroleum. Bio-based alternatives to xylene will offer a promising opportunity for reduction in the carbon footprint of the automotive industry with enough alternatives to meet their growing demands for sustainability.

However, new manufacturing processes are also helping to utilize xylene more efficiently, generating less waste and emissions. High-performance, low-emitting xylene-based products now can provide xylene’s qualities to automotive applications while meeting environmental demands.

Xylene in Hybrid and Electric Vehicles

The use of xylene is also changing in line with the transition that is happening within the automotive industry as it has started to go electric and hybrid. Xylene has, for a long time, been linked with internal combustion but lately, the use of xylene-based coatings and plastics has been on an upward trend in hybrid and electric vehicles. On the whole, the range of electric vehicles tends to improve with the use of lightweight energy-efficient material. The use of xylene-based materials could increase the range and improve the efficiency of a vehicle by reducing the weight.

Hybrid vehicles, where internal combustion engines are coupled with electric power, will also increasingly drive the market. In applications such as in an engine, for example, they require lubricants which can be used under the high pressure and friction of both engine types. In such applications, xylene-based products are excellently suited to fulfill such demands.

Challenges and Opportunities for Xylene in the Automotive Industry

Despite its significant contribution in the automotive industry, the industry is still beset by problems regarding the cost and environmental concerns of xylene. Reeling under the fluctuating price of petrochemicals as well as the pressure to produce more stringent regulations pushes the manufacturers to find new alternatives to xylene; however, its special properties make xylene a vital part of additives in fuel as well as high-performance coatings in automobiles for the next few years.

New avenues for innovation exist because auto manufacturers seek to balance the need for performance with environmental stewardship in the production of vehicles. As this industry evolves further into electric and hybrid vehicles, the role of xylene-based materials in supporting improved fuel efficiency and reduced emissions will grow.

Final Thoughts

Xylene is a very important factor in the efficiency in the amelioration of automobile performance because of its application in fuel additives, paints and coatings, plastics and rubber production, and lubricant products. Its unique chemical properties make it a commodity that should not be omitted in the production of high-performance durable vehicles. However, its environmental concerns remind users to work out a better way of using this product by finding alternative products.

Therefore, the place of xylene is changing as the entire automobile industry moves towards greener technology. New prospects involving electric and hybrid vehicles require balancing performance efficiency and sustainability. Here, xylene will be a major constituent in future automotive advancements.

Does Your Car Need High Mileage Oil? (Signs You Should Switch)

Does Your Car Need High Mileage Oil? (Signs You Should Switch) Discover More As vehicles age, their engines undergo significant wear, leading to reduced efficiency and potential breakdowns. One of the most effective ways to maintain an older engine is by switching to high-mileage oil, specially formulated for cars with 75,000 miles or more. But how do you know if your car needs it? What are the key benefits, drawbacks, and alternatives? And why should you consider Ruamnza Xrace Pro Oil for your high-mileage vehicle?

Does Your Diesel Engine Need a Special Oil? (The Truth Revealed)

Does Your Diesel Engine Need a Special Oil? (The Truth Revealed) Discover More When it comes to maintaining a diesel engine, one of the most critical decisions you’ll make is choosing the right oil. Diesel engines operate under extreme conditions—high compression, intense heat, and heavy loads—which means they require a lubricant that can withstand these challenges. But does your diesel engine really need a special oil, or can you use any high-quality motor oil? In this comprehensive guide, we’ll uncover the

What is Anti-Freeze Coolant? Types, Colors & How to Use

What is Anti-Freeze Coolant? Types, Colors & How to Use Discover More Anti-freeze coolant, also known as engine coolant or radiator fluid, is a specially formulated liquid that regulates engine temperature, prevents overheating in summer, and protects against freezing in winter. It is a mixture of water, ethylene glycol or propylene glycol, and chemical additives that enhance engine efficiency and longevity. Without proper coolant, engines can suffer from: Overheating (leading to warped cylinder heads or blown gaskets) Freezing (causing cracked engine blocks in cold climates) Corrosion (damaging radiators,

What is ATF? Types of Transmission Fluid & When to Change It

What is ATF? Types of Transmission Fluid & When to Change It Discover More Transmission fluid is one of the most critical yet often overlooked components in a vehicle’s maintenance routine. Whether you drive an automatic, manual, continuously variable transmission (CVT), or dual-clutch transmission (DCT) vehicle, the right transmission fluid ensures smooth operation, longevity, and peak performance. What is Automatic Transmission Fluid (ATF)? Automatic Transmission Fluid (ATF) is a specialized lubricant designed to reduce friction, cool transmission components, and facilitate smooth

Fuel Injector Cleaner: Does It Really Work? (Analysis, Benefits, and Top Picks)

Fuel Injector Cleaner: Does It Really Work? (In-Depth Analysis, Benefits, and Top Picks) Discover More Modern engines rely on precise fuel delivery to maintain performance, efficiency, and emissions compliance. Fuel injectors play a critical role in this process by atomizing fuel into a fine mist for optimal combustion. However, over time, carbon deposits, varnish, and contaminants can clog injectors, leading to poor engine performance. Fuel injector cleaners are chemical additives designed to dissolve these deposits and restore injector efficiency. But do they