Lithium Grease Explained: Uses, Benefits, and Applications

Lithium lubricating grease is one of the most versatile and widely used greases in various industries. It has an even high melting point with water resistance and some of the greatest lubrication properties. So, it has almost become an integral component in automotive, industrial, and even household applications. The following guide, therefore, delves into the uses, benefits, and applications of lithium grease explaining why it may be preferred for many tasks involving lubrication. We will also talk about the types of grease and how to go about making a proper choice for our needs.

What is Lithium Grease?

As formulated, lithium grease is a multi-purpose grease with a thickening agent derived from lithium hydroxide. Its color is usually white or light, while it has a smooth and buttery texture that makes it easy to apply. It diminishes friction well, aids in the prevention of rust and corrosion, and tolerates extreme temperatures; hence it is suitable for various applications.

Lithium Grease Properties

High Melting Point: Lithium grease has a high dropping point (the temperature at which it starts to melt), typically around 190-220°C (374-428°F), allowing it to perform well in high-temperature environments.

Water Resistance: It offers excellent resistance to water washout, making it ideal for applications exposed to moisture, rain, or humidity.

Oxidation Stability: Lithium grease maintains its lubricating properties over time, even in harsh conditions, which helps extend the life of the machinery or components.

Adhesive Properties: It sticks well to metal surfaces, ensuring long-lasting lubrication and reducing the need for frequent reapplication.

Versatility: Lithium grease can be used in a wide range of applications, from automotive and industrial machinery to household appliances.

Types of Lithium Grease

There are several types of lithium grease available, each designed for specific applications:

Lithium Complex Grease: This grease contains complexing agents that enhance its properties, such as higher temperature resistance, improved water resistance, and increased load-carrying capacity. It is commonly used in heavy-duty industrial applications.

White Lithium Grease: This type is the most common and versatile form of lithium grease. It is suitable for general-purpose lubrication tasks, including automotive, marine, and household applications. Its white color makes it easy to identify and monitor the application.

Moly Lithium Grease: This grease contains molybdenum disulfide (moly), which provides additional protection against extreme pressure and heavy loads. It is ideal for applications involving high stress, such as automotive chassis, bearings, and construction equipment.

What is Lithium Grease Used For

Lithium grease uses in a wide variety of lithium grease applications across different industries due to its versatility and excellent lubrication properties. Here are some of the most common uses:

1. Automotive Applications

- Chassis Lubrication: Lithium grease is often used for lubricating chassis components, such as ball joints, tie rod ends, and suspension parts. Its ability to withstand high temperatures and resist water makes it ideal for these applications.

- Wheel Bearings: Many automotive enthusiasts and mechanics use lithium grease for wheel bearings, especially in trailers and light trucks. It provides long-lasting lubrication and protects against corrosion.

- Door Hinges and Locks: White lithium grease is perfect for lubricating door hinges, locks, and latches, ensuring smooth operation and reducing squeaks.

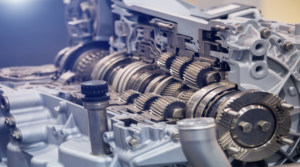

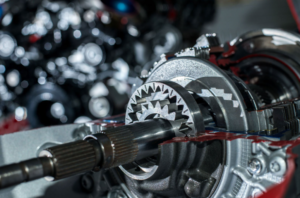

2. Industrial Applications & Agricultural Grease

- Machinery Lubrication: In industrial settings, lithium grease is widely used for lubricating bearings, gears, and other moving parts of machinery. It helps reduce friction, wear, and tear, thereby extending the life of the equipment.

- Electric Motors: Due to its excellent water resistance and high-temperature stability, lithium grease is suitable for lubricating electric motor bearings, ensuring smooth operation and reducing the risk of overheating.

3. Household Applications

- Appliance Maintenance: Lithium grease is ideal for maintaining household appliances, such as garage door tracks, hinges, and sliding doors. It ensures smooth movement and prevents rust and corrosion.

- Bicycle Maintenance: Cyclists often use white lithium grease to lubricate bike chains, gears, and other moving parts, ensuring optimal performance and reducing wear and tear.

4. Marine Applications

- Boat Trailers: Lithium oil grease’s water resistance makes it perfect for lubricating boat trailer wheel bearings and other components exposed to water.

- Marine Engines: It provides effective lubrication for marine engines, protecting against rust and corrosion in a water-rich environment.

Benefits of Using Lithium Grease

Lithium grease is pretty versatile and advantageous in a great number of lubrication applications. Some key benefits of lithium grease are as follows:

- Long-lasting lubrication: It adheres pretty well to surfaces, thus providing excellent long-lasting lubrication properties and minimizes the necessity of reapplying it frequently.

- Water Resistance: This is a great characteristic that makes it very appropriate for applications exposed to moisture, like marine and outdoor equipment.

- High temperature resistance: Lithium greases can tolerate heavy temperatures-they are used for automotive and industrial applications whereby there is a possibility of temperatures affecting the application.

- Corrosion Protection: It creates a protective barrier on metal surfaces that helps to check the corrosion and rust.

- Versatility: It can range from automotive to a house due to the fact that it can accommodate a wide application scope.

How to Apply Lithium Grease

Proper application of lithium grease ensures optimal performance and extends the life of your equipment. Here’s a step-by-step guide on how to apply it:

- Clean the Surface: Before applying lithium grease, clean the surface thoroughly to remove dirt, dust, and old grease. This ensures proper adhesion and effective lubrication.

- Apply the Grease: Use a grease gun, brush, or your fingers to apply a thin, even layer of lithium grease to the surface. Avoid over-applying, as excess grease can attract dirt and debris.

- Reapply as Needed: Monitor the lubrication periodically and reapply as needed, especially in high-use or high-stress applications.

Choosing the Right Lithium Grease for Your Needs

Selecting the right type of lithium grease depends on the specific application and operating conditions. Here are some factors to consider when choosing the right lithium grease:

- Temperature Range: Consider the temperature range of the application. For high-temperature environments, opt for lithium complex grease.

- Load-Carrying Capacity: If the application involves heavy loads or high pressure, choose moly lithium grease for added protection.

- Water Exposure: For applications exposed to water or moisture, select a grease with superior water resistance, such as white lithium grease.

Final Thoughts

It is considered one of those extremely versatile greases which encompasses a wide range of uses from the application in automotive and industrial use to household and marine tasks. Owing to its high-temperature stability, water resistance, and long-lasting lubrication, lithium grease has emerged as one of the most widely used greases for a number of lubrication requirements. It can be confidently decided which type of lithium grease to use for specific applications if different types of this grease are understood.

Whether you are maintaining a vehicle, lubricating industrial machinery, or making sure household appliances are running smoothly, lithium grease is the answer to quality lubrication and protection. Includes lithium grease in your regular maintenance schedule and assures that friction is reduced, corrosion is prevented and, thus, the lifespan of your costly equipment is extended.

FAQs

Grease lithium is a high-performance, multi-purpose lubricant made by mixing lithium soap (a thickener) with base oil and additives. It is widely used for lubricating metal parts in various industries due to its high temperature resistance, water resistance, and excellent mechanical stability.

White lithium grease is a multipurpose lubricant made from lithium soap thickener and base oils. It’s commonly used in electric motors to reduce friction, prevent wear, and protect against moisture and corrosion.

Lithium grease is a high-performance lubricant made from base oil, lithium soap thickener, and additives like anti-wear agents and corrosion inhibitors. It offers excellent temperature resistance (-30°C to 150°C), water resistance, and mechanical stability, making it ideal for automotive, industrial, marine, and household applications. The lithium soap thickener gives it a smooth, adhesive texture, ensuring long-lasting lubrication and protection against wear and rust. Its versatility makes it one of the most widely used greases in various industries.

Calcium Grease: Great water resistance, low-temperature use.

Lithium Grease: Better for high temperatures and more versatile, suitable for various applications.

Lithium grease offers better high-temperature stability, water resistance, and versatility compared to regular greases made with different thickeners.

- Limited performance under extreme pressure

- Not ideal for high-speed bearings

- Environmental concerns

- Limited chemical resistance

Alternatives include calcium sulfonate grease (water-resistant), polyurea grease (high temperature), silicone grease (for rubber/plastic), and PTFE grease (chemical resistance).

- Silicone Grease: Best for rubber, plastic, and electrical applications.

- Lithium Grease: Ideal for metal-to-metal lubrication in automotive and industrial uses.

Does Your Car Need High Mileage Oil? (Signs You Should Switch)

Does Your Car Need High Mileage Oil? (Signs You Should Switch) Discover More As vehicles age, their engines undergo significant wear, leading to reduced efficiency and potential breakdowns. One of the most effective ways to maintain an older engine is by switching to high-mileage oil, specially formulated for cars with 75,000 miles or more. But how do you know if your car needs it? What are the key benefits, drawbacks, and alternatives? And why should you consider Ruamnza Xrace Pro Oil for your high-mileage vehicle?

Does Your Diesel Engine Need a Special Oil? (The Truth Revealed)

Does Your Diesel Engine Need a Special Oil? (The Truth Revealed) Discover More When it comes to maintaining a diesel engine, one of the most critical decisions you’ll make is choosing the right oil. Diesel engines operate under extreme conditions—high compression, intense heat, and heavy loads—which means they require a lubricant that can withstand these challenges. But does your diesel engine really need a special oil, or can you use any high-quality motor oil? In this comprehensive guide, we’ll uncover the

What is Anti-Freeze Coolant? Types, Colors & How to Use

What is Anti-Freeze Coolant? Types, Colors & How to Use Discover More Anti-freeze coolant, also known as engine coolant or radiator fluid, is a specially formulated liquid that regulates engine temperature, prevents overheating in summer, and protects against freezing in winter. It is a mixture of water, ethylene glycol or propylene glycol, and chemical additives that enhance engine efficiency and longevity. Without proper coolant, engines can suffer from: Overheating (leading to warped cylinder heads or blown gaskets) Freezing (causing cracked engine blocks in cold climates) Corrosion (damaging radiators,

What is ATF? Types of Transmission Fluid & When to Change It

What is ATF? Types of Transmission Fluid & When to Change It Discover More Transmission fluid is one of the most critical yet often overlooked components in a vehicle’s maintenance routine. Whether you drive an automatic, manual, continuously variable transmission (CVT), or dual-clutch transmission (DCT) vehicle, the right transmission fluid ensures smooth operation, longevity, and peak performance. What is Automatic Transmission Fluid (ATF)? Automatic Transmission Fluid (ATF) is a specialized lubricant designed to reduce friction, cool transmission components, and facilitate smooth

Fuel Injector Cleaner: Does It Really Work? (Analysis, Benefits, and Top Picks)

Fuel Injector Cleaner: Does It Really Work? (In-Depth Analysis, Benefits, and Top Picks) Discover More Modern engines rely on precise fuel delivery to maintain performance, efficiency, and emissions compliance. Fuel injectors play a critical role in this process by atomizing fuel into a fine mist for optimal combustion. However, over time, carbon deposits, varnish, and contaminants can clog injectors, leading to poor engine performance. Fuel injector cleaners are chemical additives designed to dissolve these deposits and restore injector efficiency. But do they

Best Railroad Engine Oils in 2025 – Boost Performance & Longevity

Best Railroad Engine Oils in 2025 – Boost Performance & Longevity Discover More The railroad industry is a backbone of global logistics, transporting millions of tons of cargo and passengers daily. Given the immense stress on locomotive engines, selecting the best railroad engine oil is crucial for optimal performance, fuel efficiency, and engine longevity. In 2025, advancements in lubrication technology have led to high-performance synthetic blends, low-ash formulations, and smart additives that enhance engine protection under extreme conditions. This guide

Best Transmission Treatments to Extend Your Vehicle’s Lifespan (2025 Guide)

Best Transmission Treatments to Extend Your Vehicle’s Lifespan Discover More Maintaining your vehicle’s transmission is crucial for ensuring longevity, smooth performance, and fuel efficiency. With advancements in automotive technology, transmission treatments have evolved significantly in 2025. This guide explores the best transmission treatments available, their benefits, and how they can help extend your vehicle’s lifespan. Understanding Transmission Systems and Their Importance A vehicle’s transmission is responsible for transferring power from the engine to the wheels, enabling smooth gear shifts and